Industry news

Tungsten Carbide Cutting Tools and Their Common Problem and Solution

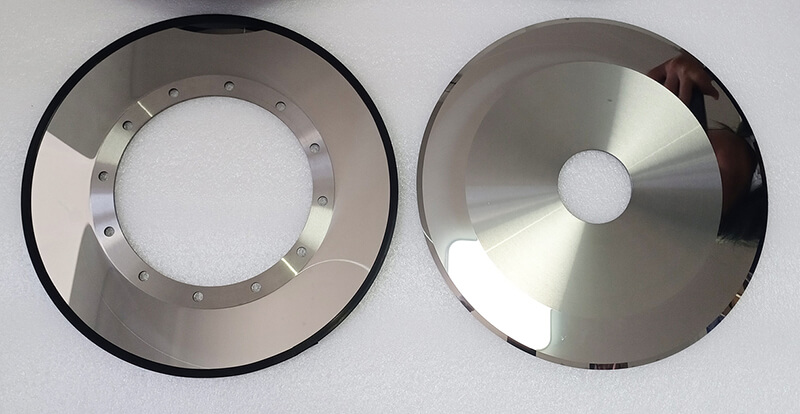

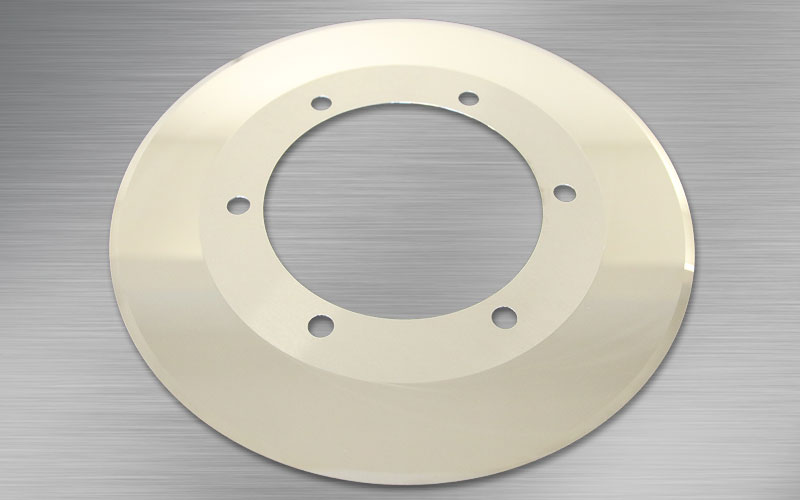

Tungsten carbide cutting tools, also known as hard alloy cutting tools, are widely used in various machining operations due to their excellent hardness, wear resistance, and high cutting speeds. These tools are typically made from tungsten carbide or other carbide-based materials combined with a binder metal such as cobalt.

Cemented carbide cutting tools come in various forms, including inserts, drills, end mills, reamers, and taps. They are designed to withstand high cutting temperatures and mechanical stresses encountered during machining processes. The cutting edges of these tools are precision-ground to ensure sharpness and accuracy.

These cutting tools offer several advantages over traditional high-speed steel tools. They have a longer tool life, allowing for extended periods of continuous cutting. They can withstand higher cutting speeds, resulting in improved productivity. Additionally, hard alloy cutting tools exhibit excellent performance when machining hard and abrasive materials like stainless steel, cast iron, and hardened steels.

The selection of a hard alloy cutting tool depends on factors such as the machining application, workpiece material, cutting parameters, and desired surface finish. Different grades and geometries of carbide inserts are available to suit specific machining requirements. Coatings, such as titanium nitride (TiN) or titanium carbonitride (TiCN), can be applied to enhance the tool's wear resistance and reduce friction.

To ensure optimal performance and tool life, proper tool maintenance is essential. This includes regular inspection of cutting edges, replacement of worn or damaged inserts, and cleaning of chips and debris. Cutting fluids or coolants are often used during machining to dissipate heat and lubricate the cutting zone, further enhancing tool performance.

Hard alloy cutting tools have revolutionized the machining industry, enabling efficient and precise cutting operations across a wide range of materials. With their exceptional hardness and durability, they continue to be a vital component in modern machining processes.

Common Problems and Solutions for Tungsten Carbide Cutting Tools

Wear: One of the most common issues with hard alloy cutting tools is wear due to the high cutting temperatures and forces involved. The cutting edges may become dull or develop chips over time.

Solution: Regularly inspect the cutting edges and replace the tool when necessary. Applying suitable coatings or using advanced wear-resistant materials can help extend the tool life. Additionally, optimizing cutting parameters such as speed, feed rate, and depth of cut can reduce wear.

Chipping or Breakage: Hard alloy cutting tools can experience chipping or breakage, especially when encountering hard or brittle workpiece materials. This can result in poor cutting performance and tool failure.

Solution: Selecting a tool with appropriate toughness and strength for the specific machining application is crucial. It's important to consider the workpiece material properties and adjust cutting parameters accordingly. Using proper cutting techniques, such as reducing cutting forces or using a more gradual entry angle, can also help prevent chipping or breakage.

Built-up Edge (BUE): During cutting, material from the workpiece can adhere to the tool's cutting edge, leading to the formation of a built-up edge. This can negatively affect surface finish and dimensional accuracy.

Solution: Employing cutting fluids or lubricants can help mitigate built-up edge formation. Additionally, selecting coatings with low adhesion properties can prevent the accumulation of workpiece material on the tool. Adjusting cutting parameters to reduce cutting forces and maintaining proper chip evacuation can also minimize BUE.

Thermal Cracking: The high temperatures generated during cutting can induce thermal stresses in the cutting tool, potentially resulting in thermal cracking or premature failure.

Solution: Using cutting tools made from high-temperature resistant alloys or incorporating cooling techniques, such as through-tool coolant or air blast, can help dissipate heat and reduce the risk of thermal cracking. Optimizing cutting parameters to minimize heat generation and providing adequate tool support can also alleviate thermal stress.

Poor Surface Finish: Inconsistent or rough surface finish is another issue that can occur with hard alloy cutting tools. This can be caused by factors like tool deflection, improper tool geometry, or inadequate cutting parameters.

Solution: Ensure the cutting tool is properly clamped and supported to minimize deflection. Choosing appropriate tool geometries, such as sharper cutting edges or optimized rake angles, can improve surface finish. Adjusting cutting parameters like feed rate, speed, and depth of cut based on the workpiece material and desired surface finish can also help achieve better results.

It's important to note that these are general problems and solutions associated with hard alloy cutting tools. The specific issues and remedies may vary depending on the type of tool, workpiece material, cutting conditions, and other factors.

Keywords: cemented carbide cutting tool, tungsten carbide blade,carbide circular blade, cemented carbide slitting blade, Tungsten Carbide Tobacco Round Blade, Tungsten Carbide Corrugated board Blades,Tungsten Carbide Wire Stripping Machine Blade,Cemented carbide lithium battery separator slitting blade,Tungsten Carbide Burrs Rotary Files,Tungsten Carbide Blade supplier, Tungsten Carbide Sharpening fine grinding Blades

Prev:Product Properties of the Carbide Valve Seat

Next:Introduction of Cemented Carbide Nozzle