Industry news

How to Use the Tungsten Carbide Anvils Correctly?

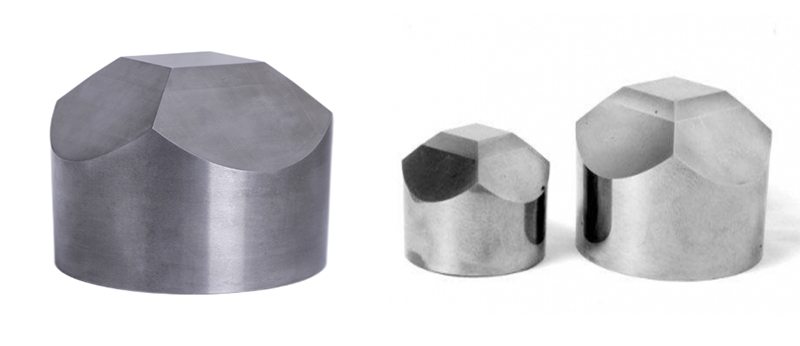

Cemented carbide anvils is an important component in the production of synthetic diamond and is subjected to high temperature and high pressure alternating load during the process of diamond synthesis, and its life duration directly determines the production cost of diamond.

Tungsten carbide anvils are specialized tools used in various high-pressure research and industrial applications. They are typically made from a compound of tungsten and carbon, known as tungsten carbide (WC). Tungsten carbide is valued for its extreme hardness, wear resistance, and high melting point, making it suitable for withstanding extreme conditions and pressures.

Application: Cemented carbide six-sided top hammer is used to synthesize artificial diamond, the synthesis process requires the highest quality and stability of cemented carbide.

Do you know how to use a carbide anvil correctly? So how to adjust it accurately?

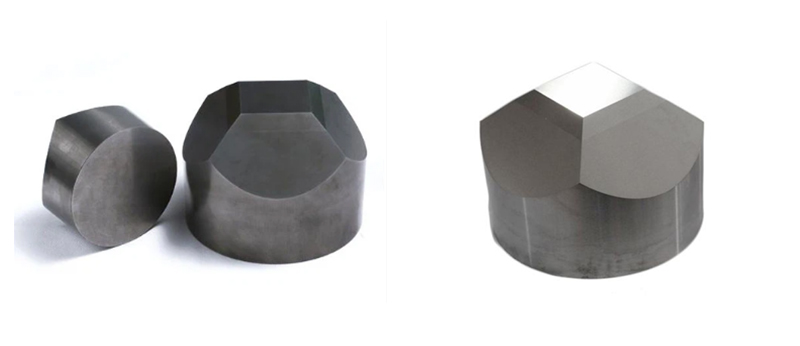

1. The cooperation between the carbide top hammer and the steel ring. The cooperation between the top hammer and the steel ring is one of the important factors affecting the service life of the top hammer. When installing the top hammer and the steel ring, the matching taper angle must be precise. The taper of the top hammer and the steel ring must be consistent. The contact surface must be greater than or equal to 90%. The press-fit height must be reasonable. The carbide top hammer must not match the size of the pad. Point contact occurs to avoid stress concentration.

2. The steel ring fastening screw can be twisted freely without great resistance.

3. The installed large pad should be in flat contact with the working cylinder piston and be well tightened.

4. When installing the top hammer, pay attention to keeping it level. You can use the correction block to check. That is, place the correction block between the two top hammers and move it gently to avoid shaking.

5. The press must have good adjustment accuracy, no leakage is allowed, and the synchronization and neutrality deviation should not exceed 0.2mm. Use a solid block to calibrate the synchronization of the six top hammers. After the alignment meets the requirements, further judgment should be made based on the synchronization and centering of the synthetic block and synthetic rod. The plug should be round, not elliptical, and not eccentric to ensure that the synthetic rod is a regular cylinder. body. There are no abnormal phenomena such as bell mouth on the end face, otherwise the centering of the top hammer should be adjusted continuously.

Some key uses and characteristics of tungsten carbide anvils:

High-pressure experiments: Tungsten carbide anvils are often used in high-pressure research, particularly in the field of materials science and condensed matter physics. They provide a means to generate extremely high pressures, often in excess of 100,000 atmospheres, to study the behavior of materials under such conditions. This is essential for understanding phase transitions, material properties at extreme pressures, and for developing new materials.

Diamond anvil cells (DACs): Tungsten carbide anvils are a key component of diamond anvil cells, which are devices used to generate high pressures within a small sample chamber. The sample is placed between the diamond anvils, and pressure is applied by compressing the anvils together. Tungsten carbide is often used as the backing material for the diamond anvils because it can withstand the high pressures without deforming.

Geological research: Tungsten carbide anvils are also used in geology laboratories to simulate the high-pressure conditions found deep within the Earth's mantle. Researchers use these anvils to study the behavior of minerals and rocks at extreme pressures, helping to shed light on geological processes and the formation of Earth's interior.

Industrial applications: Tungsten carbide is widely used in various industrial applications due to its exceptional hardness and wear resistance. Tungsten carbide anvils are used in industries such as metalworking, mining, and oil drilling to withstand the wear and tear of heavy-duty operations.

Durability: Tungsten carbide anvils are highly durable and can maintain their hardness and structural integrity even under harsh conditions. This makes them suitable for long-term use in high-pressure experiments and industrial settings.

Temperature resistance: Tungsten carbide has a high melting point, which allows it to maintain its properties at elevated temperatures. This is important when generating high pressures, as the anvils can become quite hot during compression.

Hunan Jetvision Industrial Co.Ltd is one of the leading Tungsten carbide manufacturers and suppliers with over 20years experience of tungsten carbide products production and technology, It's a professional supplier which provide kinds of tungsten carbide products, such as cemented carbide rod blank, cemented carbide wire drawing dies, tungsten carbide seal rings, tungsten carbide plate, tungsten carbide bushing, carbide tube, tungsten carbide button, carbide mining inserts, carbide blade, tungsten carbide strip, carbide dies, carbide brazed tips, tungsten carbide no standard products, carbide studs, tungsten carbide customized components which are widely used in machinery, mining, construction, oil and drill, industrial engineering etc.

Keyword: Carbide anvils supplier, tungsten carbide anvils in stock, buy cheap cemented carbide anvils, Tungsten carbide anvils manufacturer, carbide anvils price list, cemented carbide anvils supplier, tungsten carbide anvils manufacturer, wholesales carbide anvils, cemented carbide valve seat in stock, buy solid carbide anvils, buy cheap carbide anvils price, Trusted tungsten carbide anvils made in China, sintered carbide anvils in stock

Prev:How to Classify Tungsten Carbide Abrasive Waterjet nozzle?

Next:Advantages of Carbide Ball Mill Tank