Industry news

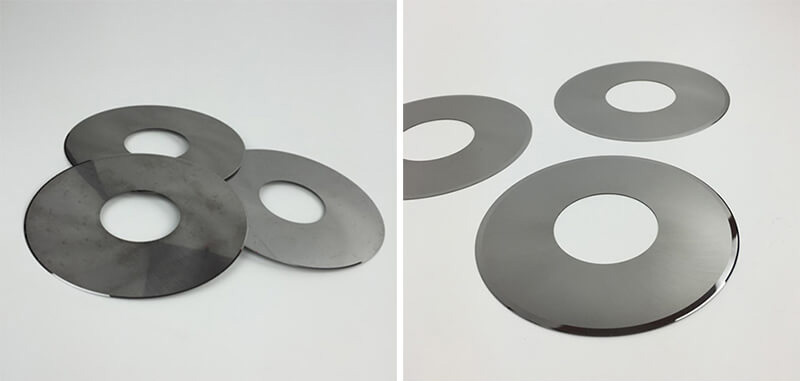

What are the Precautions for the use of Carbide Circular Saw Blades?

As an important tool in the metal processing industry, the efficiency and safety of the use of carbide circular saw blades are directly related to the quality of processing and the safety of operators. Therefore, in the use of carbide circular saw blades, must follow certain precautions to ensure its normal operation and extend the service life.

1. Saw blades of different specifications and uses are designed with different head angles and base forms, so try to use them according to their corresponding occasions.

2. The size and shape accuracy of the spindle and clamping plate of the equipment have a great influence on the use effect, and should be checked and adjusted before installing the saw blade. In particular, the contact surface between the clamping plate and the saw blade affects the clamping force causing displacement and slippage factors must be eliminated.

3. Pay attention to the working condition of the saw blade at any time, abnormalities, such as vibration, voice, processing surface away from the material, you must stop the machine in time to adjust, and timely repair and grinding, to maintain the peak profit.

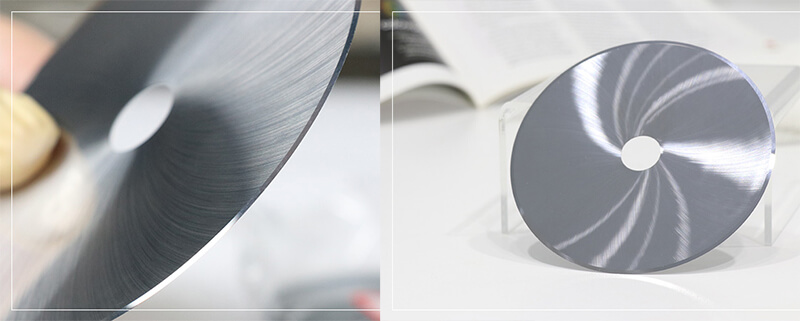

4. Sharpening the saw blade should not change its original angle, to avoid the head of the blade localized sudden heat and cold, please professional sharpening; temporarily unused saw blade should be hung vertically, avoid long time flat, and should not be stacked on the pressure of things, the head of the blade should be protected, no collision.

5. The equipment itself should have good mechanical properties, firmly installed and fixed, no vibration, etc.

6. the spindle of the mechanical equipment should be flat, straight, tolerance is not lower than the national standard, the tolerance of the spindle of the national standard for the earth 0.01mm. saw blade has a blunt feeling, emergency when grinding, grinding should choose the appropriate size of the diamond grinding wheel, but also should be used with the use of coolants

7. After resharpening, the original cutting angle of the saw teeth should be maintained, and the back angle and the saw plate should be resharpened and adjusted at the same time so as to achieve satisfactory results. At present, there are a lot of resharpening equipments on the market, whose equipments themselves are not up to the requirements in terms of precision and grinding conditions, not to mention that they can resharpen a good product. Before using the new or repaired saw blade, it should be idled for one cycle, and then check whether the saw blade is firmly installed to prevent the saw blade from slipping.

8. Saw blade reaming should not exceed the original aperture diameter of 15mm, due to each saw blade manufacturer in the saw blade factory, according to its diameter, has been adjusted to the saw blade stress, otherwise it will cause the loss of tension will be affected by the cutting effect of the saw blade; choose a reasonable number of teeth, more conducive to the cutting effect and prolongation of the service life of the saw blade.

Hunan Jetvision Industrial Co.Ltd is one of the leading Tungsten carbide manufacturers and suppliers with over 20years experience of tungsten carbide products production and technology, It's a professional supplier which provide kinds of tungsten carbide products, such as tungsten carbide cutter blade, carbide ball, carbide ball mill tank, carbide grinding ball jar, cemented carbide rod blank, cemented carbide wire drawing dies, tungsten carbide seal rings, tungsten carbide plate, tungsten carbide bushing, carbide tube, tungsten carbide button, carbide mining inserts, carbide blade, tungsten carbide strip, carbide dies, carbide brazed tips, tungsten carbide no standard products, carbide studs, tungsten carbide customized components which are widely used in machinery, mining, construction, oil and drill, industrial engineering etc.

Keyword: cemented carbide cutter blade supplier, carbide circular cutting knives manufacturer, carbide circular cutting discs price, Carbide disc knives supplier, tungsten carbide blade in stock, buy cheap cemented Carbide disc cutters, Tungsten carbide circular blades manufacturer, carbide disc knives price list, cemented carbide disc cutter supplier, wholesales carbide circular blade, Tungsten Carbide Slitting Blade Circular Knives in stock, buy solid carbide circular knives, buy cheap carbide circular blade price, Trusted tungsten carbide disc blade made in China, sintered carbide circular blade in stock

Prev:What is the Characteristics and Application of Precision Tungsten Carbide Bushing?

Next:Can Cemented Carbide be Used in High Speed Cutting and Wear Resistance Scenarios?