Industry news

How to Choose the Suitable Carbide Saw Blade?

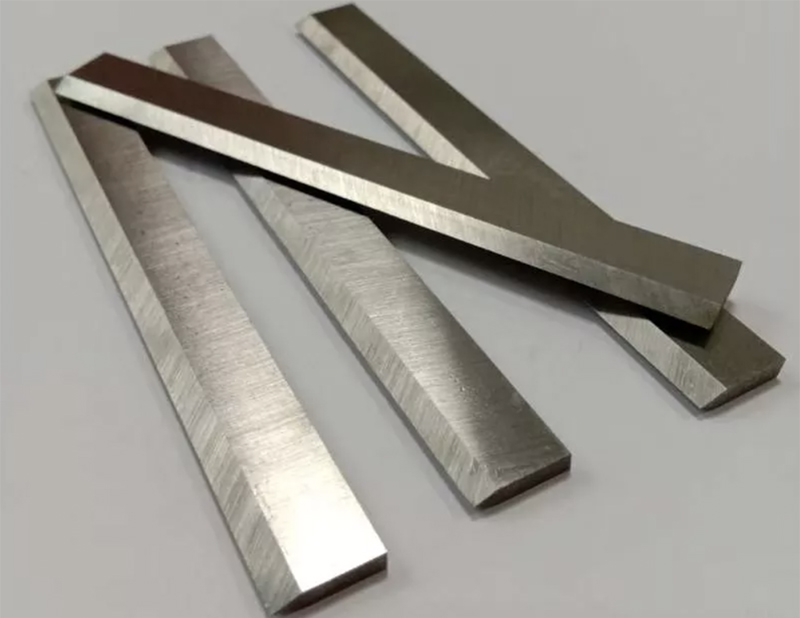

Tungsten carbide tipped saw blades can cut almost everything from asbestos to Zirconium, including paper, plastics, rubber, steel, insulation, aluminum, and even food, as well as every kind of wood in the world and all the wood composites. Carbide saw blades play a vital role in the metal sawing industry.

How to choose the suitable carbide saw blade?

1. Material selection: Aluminum cutting machine saw blades generally use carbide, and good equipment generally uses tungsten carbide alloy steel.

2. Selection of saw blade diameter: Under the same thickness, the size of the blade diameter determines the cutting output. Small diameters result in low output, whereas large diameters result in high output. The outer diameter of the saw blade is selected according to different circular saw machine models. Saw blade with matching diameter.

3. Selection of the number of teeth. Generally speaking, the more the number of teeth, the more edges can be cut per unit time and the better the cutting performance. However, more cutting teeth require more carbide, and the price of the saw blade will be higher, but the saw teeth If it is too dense, the chip capacity between the teeth becomes smaller, which can easily cause the saw blade to heat up. In addition, there are too many saw teeth. If the feed rate is not matched properly, the amount of cutting per tooth will be very small, which will intensify the friction between the cutting edge and the workpiece, affecting the quality of the blade. service life. Usually the tooth spacing is 15-25mm, and a reasonable number of teeth should be selected according to the material being sawed.

Blade Type:

Different types of carbide saw blades are designed for specific cutting tasks, such as woodworking, metal cutting, tile cutting, concrete cutting, etc. Make sure to choose the type that matches your specific job.

Blade Diameter and Teeth Count:

Blade diameter and teeth count affect cutting speed and accuracy. Generally, larger diameter blades are suitable for rough cuts, while smaller ones are better for fine cuts. More teeth generally result in smoother, more precise cuts but may be slower.

Cutting Material:

The material you are cutting is a crucial consideration. Different carbide saw blades are designed for various materials, including wood, metal, plastic, tile, concrete, and more. Ensure you choose a blade suitable for the material you are working with.

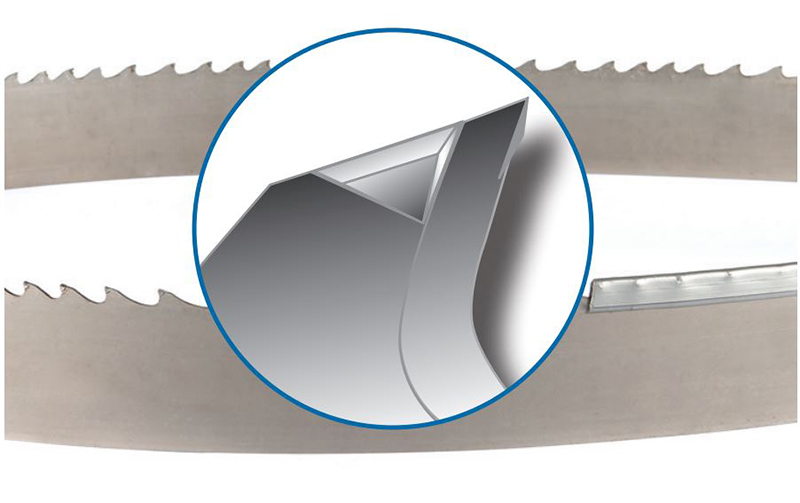

Tooth Design:

The tooth design also influences the cutting result. For example, alternate top bevel (ATB) teeth are suitable for fast, rough cuts, while triple-chip grind (TCG) teeth are better for cutting abrasive materials. Choose the tooth design that suits your cutting needs.

Blade Quality:

Blade quality is vital for cutting performance and longevity. High-quality carbide saw blades may come at a higher cost but are generally more durable and provide better cutting results.

Arbor Size and Blade Compatibility:

Ensure that the carbide saw blade you choose has the correct arbor size and is compatible with your saw or power tool.

Budget:

Your budget is also a factor in selecting a carbide saw blade. Balance quality and performance with your budget constraints.

Brand and Reviews:

Choose a blade from a reputable manufacturer and read user reviews and recommendations to learn about others' experiences and advice.

In summary, choosing the suitable carbide saw blade involves considering multiple factors, including the material you are cutting, the type of work you are doing, your budget, and the compatibility with your equipment. Based on these factors, you can select the blade type and specifications that best suit your needs. If in doubt, consider seeking advice from professionals or sales representatives.

Hunan Jetvision Industrial Co.Ltd is a professional supplier and manufacturer which offer kinds of tungsten carbide products, such as cemented carbide cutting tools, carbide insert, carbide tips, carbide nozzle, carbide valve seat, tungsten carbide blade, carbide rod,carbide dies, carbide tube, carbide sheet, carbide ball, carbide seal rings, carbide vale seat,etc. high quality and low price

Keywords: cemented carbide saw blade supplier, cemented carbide cutting tool, tungsten carbide blade,carbide circular blade, cemented carbide slitting blade, Tungsten Carbide Tobacco Round Blade, Tungsten Carbide Corrugated board Blades,Tungsten Carbide Wire Stripping Machine Blade,Cemented carbide lithium battery separator slitting blade,Tungsten Carbide Burrs Rotary Files,Tungsten Carbide Blade supplier, Tungsten Carbide Sharpening fine grinding Blades

Prev:Production Process of the Carbide Valve Seat

Next:How to Classify Tungsten Carbide Abrasive Waterjet nozzle?