Industry news

What are the Properties of Cemented Carbide Cutting Tools to Gain a Broad Market?

Carbide tools are popular in the machining industry because of their excellent properties. The hardness of the tool material is usually high, and the minimum requirement is higher than the hardness of the workpiece being machined. The high requirements for the tool performance including wear resistance, heat resistance, thermal conductivity, toughness, etc..

1. High hardness and wear resistance

Tool material wear resistance refers to the ability to resist wear, in general, the higher the hardness of the tool material, the better the wear resistance.

The hardness of the tool material should be higher than the material being processed to ensure that it can cut high-strength workpieces and remain sharp in high-temperature, high-speed machining.

Market value: excellent wear resistance can extend tool life, reduce the frequency of replacement and downtime, reduce production costs.

2. High temperature performance and heat resistance

Heat resistance is usually measured by the material's ability to maintain high hardness at high temperatures, i.e. thermal hardness, the better the heat resistance, the stronger the tool material's ability to resist deformation and wear in the cutting process.

During high-speed cutting, a large amount of heat is generated between the tool and the workpiece, and cemented carbide needs to maintain its hardness and stability at high temperatures.

Market value: support high speed machining, improve efficiency while ensuring cutting accuracy.

3. Good thermal conductivity.

The thermal conductivity of cutting tool material is expressed by thermal conductivity. With large thermal conductivity and good thermal conductivity, the heat generated during cutting is easily conducted out, thus reducing the temperature of the cutting part of the tool, alleviating the wear and tear of the tool, and improving the ability of the cutting tool material to withstand thermal impacts and resist thermal cracking.

Rapid heat dissipation reduces the temperature in the cutting area and prevents premature failure of the tool due to heat accumulation.

Market value: Improve cutting efficiency while extending tool life.

4. Sufficient strength and toughness. The material of the cutting part of the tool has to withstand a lot of cutting force and impact during cutting, so the tool material must have sufficient strength and toughness.

In intermittent cutting or processing of uneven hardness of the material, the tool must have impact resistance to prevent chipping or fracture.

Market Value: Reduced tool damage, especially under heavy loads or complex machining conditions.

5. Oxidation resistance and chemical stability

The surface of the tool must be resistant to oxidation and chemical corrosion to avoid undesirable chemical reactions with the material being machined.

Market value: Adapt to more material types (e.g. high-temperature alloys, stainless steel, etc.), expanding application areas.

6. Optimized cutting performance and good processability.

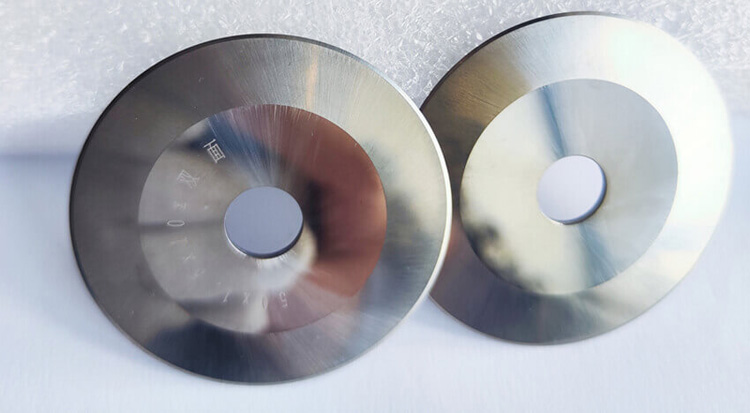

Cutting tool materials should have good machinability, including forging, welding, cutting, heat treatment, grindability, etc., in order to facilitate the tool manufacturing circular inserts.

Cutting performance should be able to adapt to a variety of machining methods (such as turning, milling, drilling) and different materials processing needs.

Market value: tools with strong versatility reduce inventory pressure and meet diversified customer needs.

To gain a broad market for carbide tools, a balance needs to be struck between high performance, cost-effectiveness and the ability to diversify applications. At the same time, the combination of technological innovation and excellent service can further enhance competitiveness.

Prev:Broken Carbide Milling Cutter Edge Wear Reasons and Solutions

Next:What’s The Difference Between Carbide Blades and Other Blades?