Industry news

What Machines are Needed to Produce Cemented Carbide Round Rod?

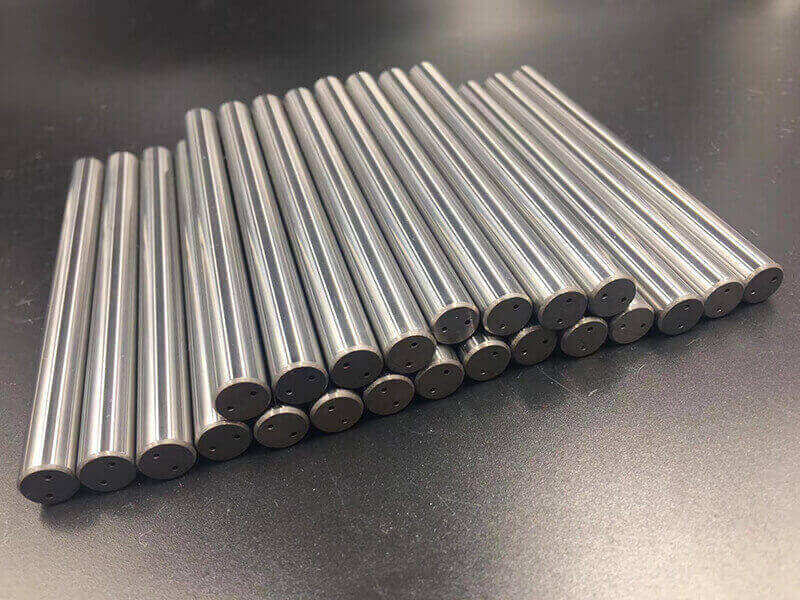

Cemented Carbide Round Rod is a round rod-shaped product made of Cemented Carbide material, which is usually used in the manufacture of cutting tools, drills, abrasives, molds and other industrial fields that require high hardness, abrasion and corrosion resistance performance of parts and tools. The preparation process of Cemented Carbide round rods includes steps such as powder metallurgy, molding, sintering, machining, and coating.

Cemented carbide is usually prepared from tungsten carbide (WC) particles with metal powders such as cobalt (Co) through a powder metallurgy process. These particles combine with cobalt during the sintering process to form a robust material with high hardness and wear resistance.

The main features of Cemented Carbide Round Bar include:

High hardness: Cemented Carbide has extremely high hardness, which enables it to maintain long tool life during high-speed cutting, grinding and other processes.

Excellent wear resistance: Cemented Carbide is able to maintain good wear resistance in high friction and high pressure environments, making it suitable for processing hard materials or high wear environments.

Corrosion resistance: Cemented Carbide is usually corrosion resistant and is suitable for some harsh working environments.

High strength: Although Cemented Carbide is a brittle material, its high strength can still provide good performance in some specific applications.

Wide adaptability: Cemented Carbide Round Rods can be designed and processed according to different application requirements, and are used to manufacture various types of cutting tools, grinding tools, molds and dies.

Cemented Carbide Round Bars have a wide range of applications in industry, providing vital support for machining and manufacturing processes.

Do you know what machines are used to produce a tungsten carbide round bar? What machines are used to produce a tungsten carbide round bar? Let's learn about the machines and equipment needed to produce tungsten carbide round rods.

The following machines and equipments are usually needed to produce tungsten carbide round rods:

Powder metallurgy equipment: powder metallurgy is one of the common methods of cemented carbide preparation. It requires powder mixing, pressing and sintering equipment, including powder mixers, presses and sintering furnaces.

Ball mill: It is used to pulverize, mix and refine the raw materials of Cemented Carbide.

Billet preparation equipment: the powder after ball milling is molded, generally using injection molding machines, extruders, etc.

High temperature heat treatment equipment: Cemented carbide needs to be sintered or heat treated at high temperature, so it needs sintering furnaces and heat treatment furnaces with high temperature environment. The sintering furnace puts the pressed or injection molded blank into the high temperature furnace for sintering treatment.

CNC machine: Used to process sintered carbide blanks for turning to form precise cylindrical shapes. Common CNC machines include lathes, milling machines, grinding machines, etc.

Precision grinding machine: used for fine machining of carbide cylinders to obtain a high degree of roundness and smoothness

Cutting equipment: used to cut the machined carbide blanks into round rods, which can use wire cutters, saws, etc.

Coating equipment: Some tungsten carbide round bars need to be coated to enhance wear resistance or other properties, and the coating equipment includes physical vapor deposition (PVD) equipment, chemical vapor deposition (CVD) equipment, and so on.

Testing and quality control equipment: including microscopes, spectrometers, hardness testers, etc., used to test the quality and performance of tungsten carbide round bars. Hardness tester, material tester, size measuring instrument, etc., used to test the hardness, strength, size and other performance parameters of cemented carbide round bars.

Cleaning and packaging equipment: equipment used for cleaning and packaging the final product. The processed tungsten carbide round bars are cleaned to remove oil and stains to ensure the cleanliness and smoothness of the product surface.

The above are just some basic equipments, the production of tungsten carbide round rods also need some auxiliary equipments, such as coolant system, refrigeration system, ventilation equipment and so on, to ensure the stability and safety of the production process. The actual production process may vary depending on the preparation method and product requirements. When designing the production line for cemented carbide round rods, it is necessary to choose the appropriate equipment according to the specific process and product characteristics.

Hunan Jetvision Industrial Co.Ltd is one of the leading Tungsten carbide manufacturers and suppliers with over 20years experience of tungsten carbide products production and technology, It’s a professional supplier which provide kinds of tungsten carbide products, such as cemented carbide rod blank,cemented carbide wire drawing dies, tungsten carbide seal rings, tungsten carbide plate, tungsten carbide bushing, carbide tube, tungsten carbide button, carbide mining inserts, carbide blade, tungsten carbide strip, carbide dies, carbide brazed tips, tungsten carbide no standard products, carbide studs, tungsten carbide customized components which are widely used in machinery, mining, construction, oil and drill, industrial engineering etc.

Keyword: Carbide round bar supplier, tungsten carbide rod in stock, buy cheap cemented carbide bar blank, Tungsten carbide rod blank manufacturer, carbide rod price list, cemented carbide blank supplier, tungsten carbide bar manufacturer, wholesales carbide blank rod, cemented carbide blank bar in stock, buy solid carbide rod blank, buy cheap carbide rod blank price, Trusted tungsten carbide rod bar made in China, sintered carbide bar rod in stock

Prev:Introduction of Tungsten Carbide Cutting Tool

Next:Tungsten Carbide Ball Mill Tank for High Performance Choice with Outstanding Advantages