Cemented Tungsten Carbide Rod

Cemented Tungsten Carbide Rod

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Produce shock-resistant turning tool bar, milling toll bar, milling tool bar, reamer, drill bit, end mill, rocker, boring cutter, countersink, gun driller, graver bit, etc.

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

Cemented Tungsten Carbide Rod as a kind of cemented carbide material, its main component is tungsten carbide powder, cobalt powder and binder and a very small amount of other precious metals mixed, using powder metallurgy method in 1300 degrees high temperature sintered, with high hardness, high strength, high temperature resistance, high wear resistance and good impact toughness, cemented carbide round bar is mainly used to make high quality tungsten steel drill bits and tungsten steel Milling cutters, gongs, drill nozzles, punches and punches and wear-resistant parts for industrial machinery and equipment. Carbide micro-perforated round bars are used in specific applications and are designed for certain special requirements in the working environment. Both sintered blanks and ground tungsten carbide rod are supplied. We can offer the shaped and customized parts in accordance with drawings.

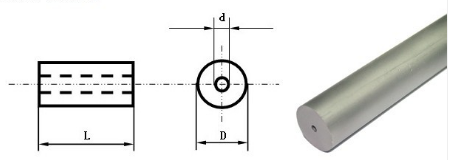

We supply solid carbide rods, carbide rods with ducts and well machined carbide rods with outer diameter from 0.4mm to 330mm, length from 2mm to 330mm. And we also could produce as your special specification.

Applications:

Tungsten carbide rods are widely used to produce shock-resistant turning tool bar, milling toll bar, milling tool bar, reamer, drill bit, end mill, rocker, boring cutter, countersink, gun driller, graver bit, etc.

Material Grades:

YG6/K20 Cemented Carbide Rods;YG8/K30 carbide solid rods ground, YG10X/k35 30°helix Cemented carbide rods, YL10.2/M25 Solid carbide rods with 2 Straight Holes

Chinese Grade | Equal to ISO Category Number | Chemical Composition | Physical Mechanical Properties | |||

WC | Co | Density | Bend Strength | Hardness | ||

% | % | G/Cm3 | N/mm2 | HRA | ||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 |

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 |

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 |

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 |

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 |

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 |

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 |

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 |

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥85.5 |

YG30 | G60 | 70 | 30 | 12.8 | ≥2750 | ≥82 |

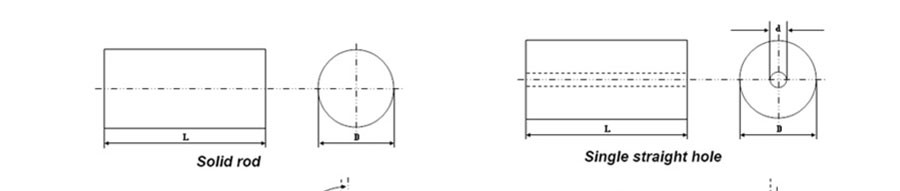

Different Type for the Cemented Carbide Rods:

Tungsten Carbide Solid Rods ground with polished surface:

Cemented Tungsten Carbide rods with single hole/ 1 straight hole specifications:

For the production of drilling, reaming and threading tools with internal coolant supply. Recommended for producing end-mills and drills. High hardness, wear resistance, and long life make it ideal for many applications.

Diameter | Tolerance | Hole Diameter | Tolerance | Length | Tolerance | Concentricity |

mm | mm | mm | mm | mm | mm | mm |

2.5 | -0.3 | 0.3 | ±0.10 | 330 | 0-+5.0 | 0.2 |

4 | -0.3 | 1 | ±0.15 | 330 | 0-+5.0 | 0.2 |

6 | -0.3 | 1 | ±0.15 | 330 | 0-+5.0 | 0.2 |

8 | -0.3 | 1.5 | ±0.15 | 330 | 0-+5.0 | 0.2 |

10 | -0.3 | 2 | ±0.20 | 330 | 0-+5.0 | 0.25 |

12 | -0.3 | 2 | ±0.20 | 330 | 0-+5.0 | 0.25 |

14 | -0.3 | 2 | ±0.20 | 330 | 0-+5.0 | 0.25 |

16 | -0.3 | 2 | ±0.20 | 330 | 0-+5.0 | 0.25 |

18 | -0.4 | 3 | ±0.25 | 330 | 0-+5.0 | 0.3 |

20 | -0.4 | 3 | ±0.25 | 330 | 0-+5.0 | 0.3 |

22 | -0.4 | 3 | ±0.25 | 330 | 0-+5.0 | 0.3 |

24 | -0.4 | 4 | ±0.30 | 330 | 0-+5.0 | 0.3 |

26 | -0.4 | 5 | ±0.35 | 330 | 0-+5.0 | 0.3 |

We can offer the shaped and customized parts in accordance with drawings. | ||||||

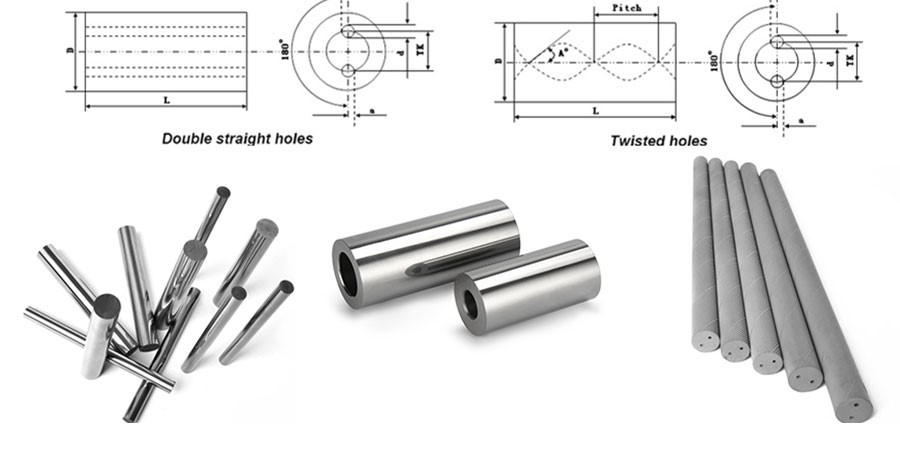

Solid carbide rods with 2 Straight Holes / Tolerance: H6

A carbide rod with two straight coolant holes is usually made into end mills for cutting or made into drill bits for mining. High hardness, wear resistance, and long life make it ideal for many applications.

Cemented Carbide Rod with spiral hole/Double Helix:

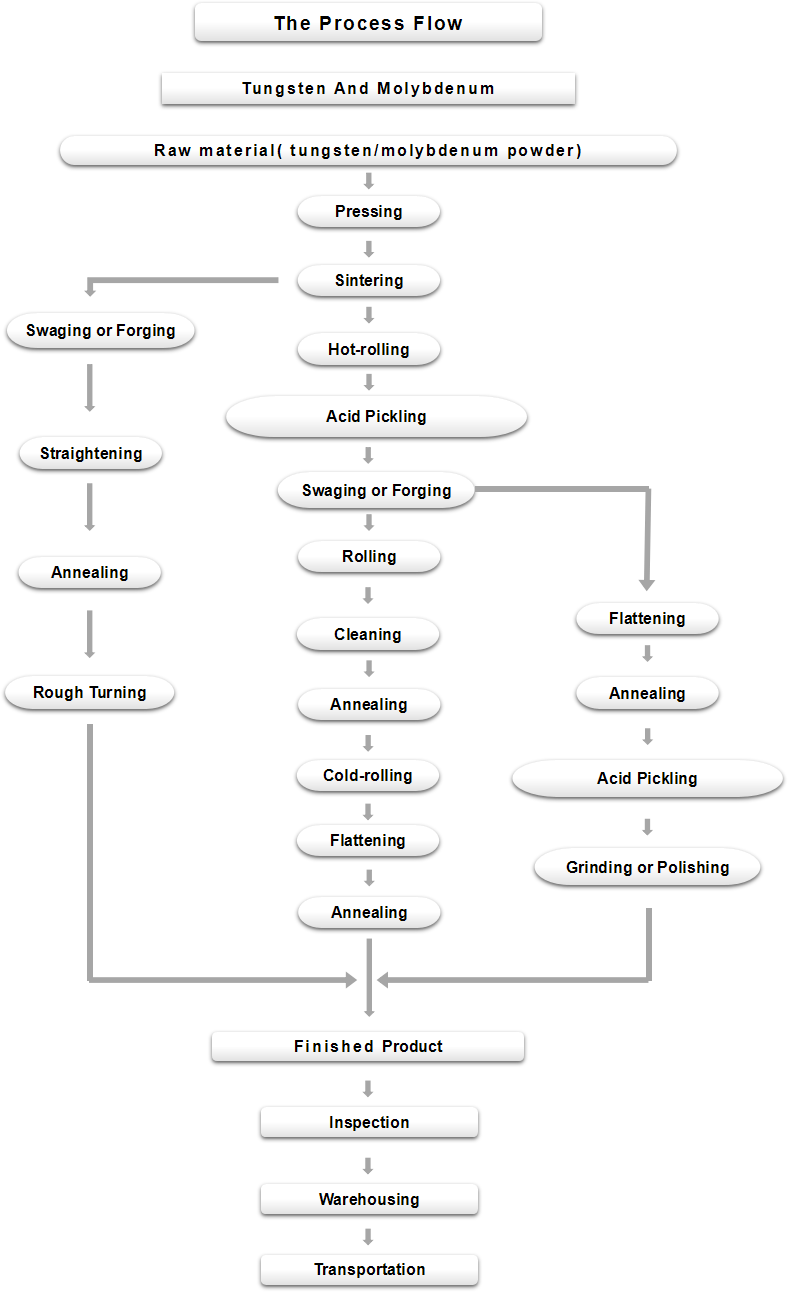

Main process flow

powder milling → formula according to grade→ wet grinding → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain a mixture → granulating → pressing → forming → low-pressure Sintering →preforms(blanks)→ measure the size → packing → storage.