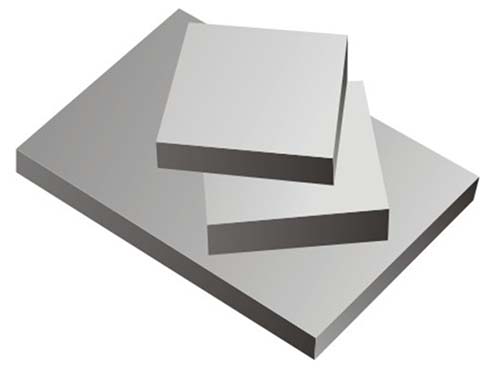

Cemented carbide plate

Tungsten Carbide Plate/Sheets

- Material:

- K10/K20/K30 or as requested

- Place of Origin:

- Hunan China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Production of high-speed cutting tools and cutting tools for hard and tough materials

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

Tungsten carbide plates also called tungsten carbide sheets and tungsten carbide blocks, divided as sintered blank and grinding. Tungsten carbide plate is mainly made of metal WC tungsten carbide powder and Co cobalt mixture by metallurgical methods of powder making, grinding, pressing, low-pressure sintering, no holes and no grit, high dimensional precision, low machining allowance, can effectively improve your production efficiency and significantly reduce processing costs.

The conventional sizes of tungsten carbide plate are as follows:

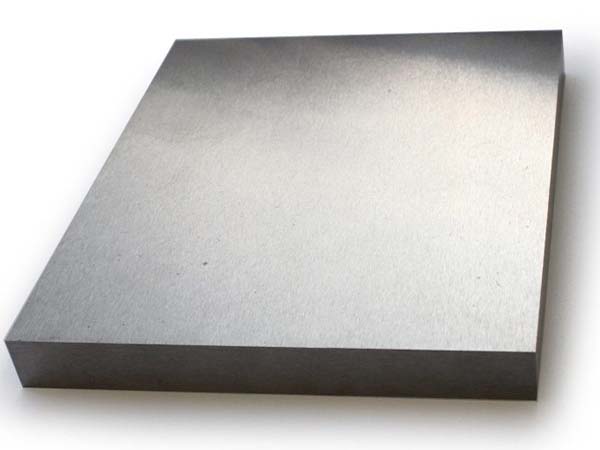

Features:

The tungsten carbide plate has high hardness, high strength, high wearing feature, high compressive strength, good stability, low impact toughness, low expand coefficient, and electric conduction. The heat conduction is similar to iron. It is an excellent material to choose for making high temperature resistance parts, corrosion parts, wear resistance parts and cutting metals, woods and other materials etc.

Application:

The production of cast iron rolls and high chrome roll knife.

Suitable for the production of discharge plate, stamping die, cold punching die, such as electronic stamping die.

Used in the production of copper, aluminum, stainless steel, cold rolled sheet, El board, Q195, SPCC, siliconsteel plate, metal, standard parts, upper and lower punch and otther high-speed mold.

Tungsten carbide plate wear resistance is higher, suitable for hardwood, logs, aluminum, copper rods, cast ironiron processing for the production of various types of motors, electronic into the mold, stamping electronic mold.

Tungsten Carbide Plate Grades:

Common grades: K10 Carbide plates, K20 carbide sheets, K30 carbide blocks.

Grade | ISO Grade | Density | Hardness | TRS |

(g/cm3) | (HRA) | (Mpa) | ||

YG6 | K20 | 14.9 | 91 | 1800 |

YG6X | K20 | 14.8 | 92 | 1800 |

YKM6A | 14.7 | 92.5 | 1800 | |

YG8 | K20-K30 | 14.8 | 90 | 1950 |

YT5 | P30 | 13 | 90.8 | 1900 |

YT14 | P20 | 11.5 | 91.5 | 1500 |

YT15 | P10 | 11.3 | 91.8 | 1450 |

YW1 | M10 | 13.1 | 91.5 | 1600 |

YW2 | M20 | 13.1 | 91 | 1600 |

YS25 | P20 P40 | 12.8 | 91.5 | 1900 |

YC30S | 12.8 | 91 | 2000 | |

ZP35 | 12.8 | 91 | 2000 | |

YC40 | 13.2 | 90 | 1850 |

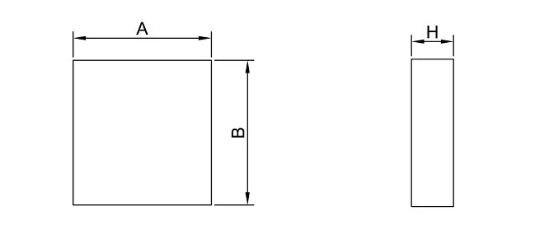

The Size of Tungsten Carbide Plate | ||

Thickness | Width | Length |

1.5-2.0 | 150 | 200 |

2.0-3.0 | 200 | 250 |

3.0-4.0 | 250 | 600 |

4.0-6.0 | 300 | 600 |

6.0-8.0 | 300 | 800 |

8.0-10.0 | 300 | 750 |

10.0-14.0 | 200 | 650 |

>14.0 | 200 | 500 |

Accept customized according to drawing or size. | ||

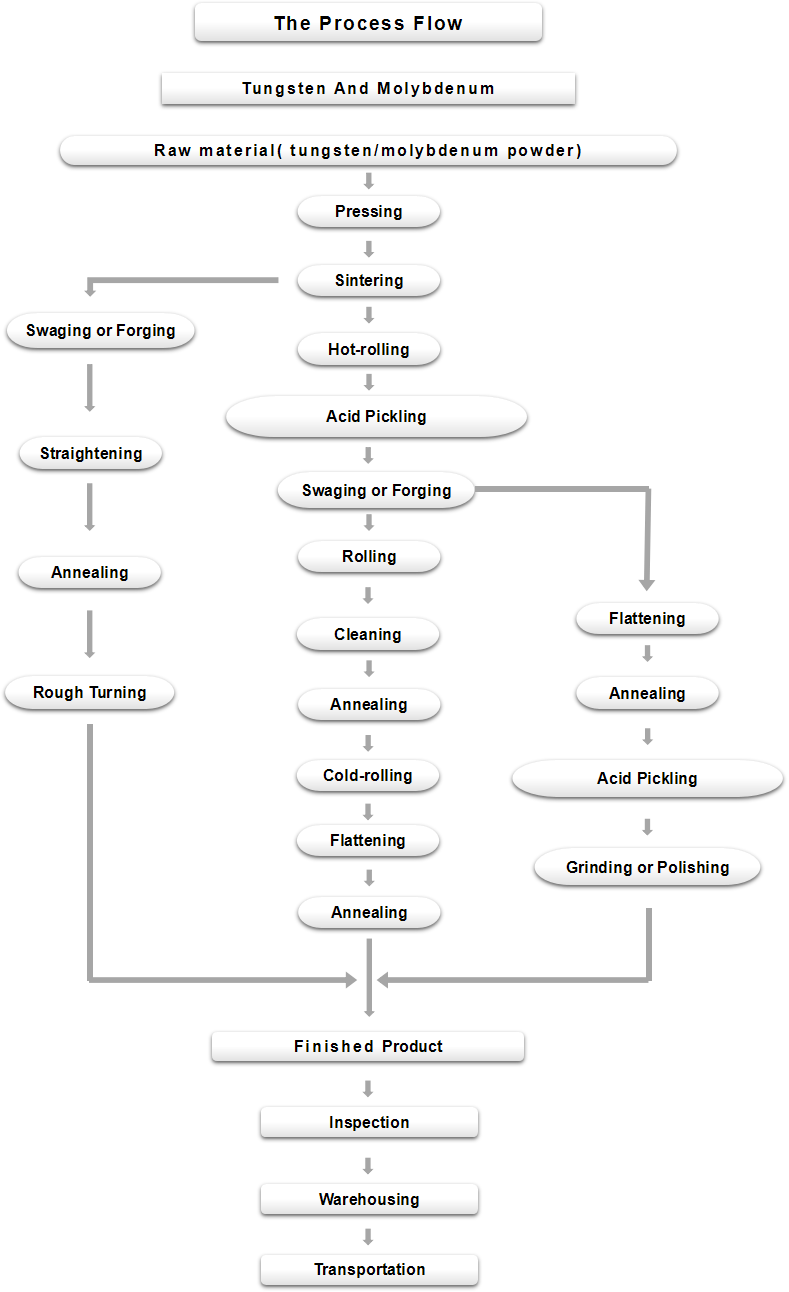

Production Process:

Powder→formulation according to the application requirements→wet grinding→mixing→crushing→drying→sieving→then adding molding agent→drying again→sieving to make the mixture→granulation→pressing→forming→sintering→forming (blank)→flaw inspection→packaging→warehousing.