Industry news

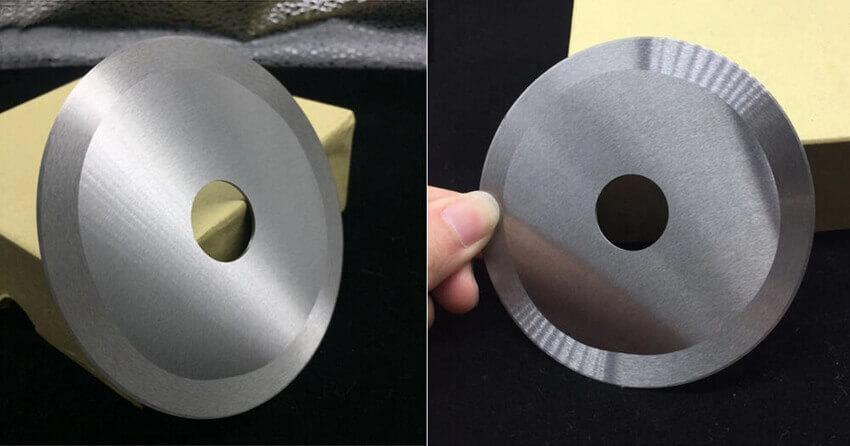

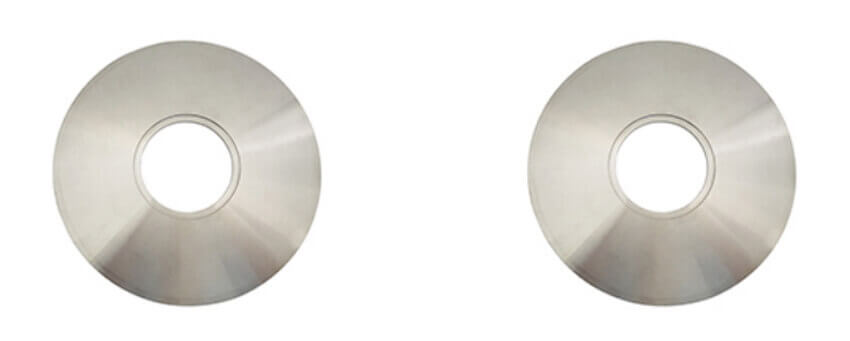

Cemented Carbide Disc Cutter Blade for Metalworking Applications

Cemented carbide cutter blade have a wide range of applications in metalworking, and their excellent hardness, wear resistance and cutting properties make them ideal for many metalworking tasks. In particular, it plays a vital role in machining processes such as cutting, dicing and milling.

The following are the specific applications and advantages of carbide circular cutting knives in metal machining:

1. High speed cutting and efficient machining

Application Scenario: carbide circular cutting discs are widely used in high-speed cutting processing, they can be used to cut various metals such as steel, aluminum, copper, etc., with high efficiency and accurate cutting effect, especially for steel, stainless steel, aluminum alloy and other difficult to machine materials.

Advantage: Due to the high hardness and wear resistance of cemented carbide materials, these tools can maintain good machining accuracy at higher cutting speeds while reducing tool wear.

2. Cutting and dividing

Application Scenario: Carbide disc cutters are commonly used for cutting and dividing metal plates, tubes, bars, etc., such as the cutting of steel plates and aluminum plates.

Advantage: Compared with the traditional high speed steel cutter, the carbide disc cutter performs more superior in cutting speed and kerf quality, and the surface finish is high after cutting, which reduces the subsequent machining process.

3. Milling and slotting

Application Scenario: In milling and grooving operation, the carbide disc cutter is widely used in the processing of metal materials, which can be used for accurate milling and turning of metal surfaces to improve the processing efficiency and processing quality. Such as grooving and keyway milling in gear manufacturing.

Advantage: The high hardness and heat resistance of cemented carbide disc cutter enable it to keep sharp under high temperature, which is suitable for continuous high load machining, and improves the efficiency and precision of milling.

4. Precision machining

Application Scenario: In aerospace, automobile manufacturing and other fields that require high machining precision, carbide disc cutters are used to machine metal parts with complex geometries.

Advantage: Carbide disc knives can still maintain high precision after a long time of work, and the tool has a longer life, which reduces the frequency of tool replacement and improves productivity.

5. High wear resistance and long life

Advantage: The main feature of Cemented Carbide material is its high wear resistance, which can effectively cope with the high abrasion environment generated in the metal processing process, so that the tool life is greatly extended. Compared with traditional tools, carbide disc cutters can be replaced less frequently, thus reducing production costs.

6. Drilling and hole machining: Carbide disc cutters can be used for drilling and hole machining of metals. They are capable of providing accurate hole diameters and surface quality for a wide range of hole machining needs in a variety of metal materials. Drilling and holemaking are common process steps in the manufacturing industry, and the use of carbide disc cutters makes these processes more efficient and reliable.

7. Special Processing Needs: Carbide tipped disc cutters also play an important role in some special metal processing tasks. For example, for the machining of high hardness metal materials or complex structures, carbide disc cutters can provide better machining results and longer service life, becoming an important part of the solution.

Cemented carbide cutter blade are widely used in the field of metal machining, especially in high speed cutting, parting, milling, precision machining, etc. They have the advantages of high machining efficiency, good abrasion resistance and long life. This makes it an important tool in modern metalworking, greatly improving productivity and reducing costs.

Hunan Jetvision Industrial Co.Ltd is one of the leading Tungsten carbide manufacturers and suppliers with over 20years experience of tungsten carbide products production and technology, It's a professional supplier which provide kinds of tungsten carbide products, such as tungsten carbide cutter blade, carbide ball, carbide ball mill tank, carbide grinding ball jar, cemented carbide rod blank, cemented carbide wire drawing dies, tungsten carbide seal rings, tungsten carbide plate, tungsten carbide bushing, carbide tube, tungsten carbide button, carbide mining inserts, carbide blade, tungsten carbide strip, carbide dies, carbide brazed tips, tungsten carbide no standard products, carbide studs, tungsten carbide customized components which are widely used in machinery, mining, construction, oil and drill, industrial engineering etc.

Keyword: cemented carbide cutter blade supplier, carbide circular cutting knives manufacturer, carbide circular cutting discs price, Carbide disc knives supplier, tungsten carbide blade in stock, buy cheap cemented Carbide disc cutters, Tungsten carbide circular blades manufacturer, carbide disc knives price list, cemented carbide disc cutter supplier, wholesales carbide circular blade, Tungsten Carbide Slitting Blade Circular Knives in stock, buy solid carbide circular knives, buy cheap carbide circular blade price, Trusted tungsten carbide disc blade made in China, sintered carbide circular blade in stock

Prev:Can Cemented Carbide be Used in High Speed Cutting and Wear Resistance Scenarios?

Next:How are Tungsten Carbide Valve Core Machined?