Industry news

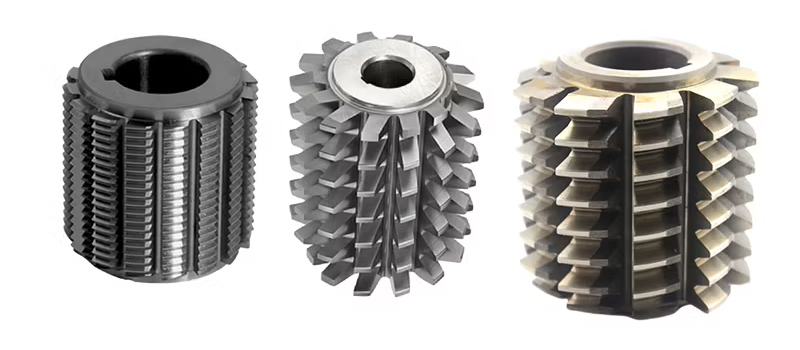

What's the Tungsten Cemented Carbide Hob?

Carbide hob is a kind of efficient tool for gear machining, which is made of carbide material.

It is widely used for machining gears, worm gears and other precision mechanical parts, and is one of the main accessories of gear hobbing machines. Compared with traditional high-speed steel hob, carbide hob has higher hardness, wear resistance and thermal stability, and plays an important role in modern manufacturing industry.

With high hardness, high temperature resistance and low wear, carbide hobs can meet the quality and efficiency requirements of on-site machining, and can improve the cutting surface finish and stabilize the cutting accuracy.

Characteristics of carbide hobs

High hardness and wear resistance: the hardness is up to HRC90 or above, suitable for machining high hardness materials or mass production.

High thermal stability: stable performance under high temperature conditions, suitable for high-speed cutting.

High machining efficiency: allows larger cutting parameters, can significantly improve productivity.

Relatively low impact resistance: carbide hobs are brittle, suitable for continuous cutting conditions, not suitable for processing environments with strong impact.

Classification of Cemented Carbide Hob

According to the processing object and use, the carbide hob is mainly divided into the following categories:

Standard hob: Used for machining straight tooth cylindrical gears and helical gears. Suitable for mass production of standard gears.

Non-standard hob: Specialized hob designed according to specific gears. Used for processing special gears or non-circular gears.

Worm gear hob: For machining worm gear flanks. With specific tooth design.

Small Module Hob: Suitable for machining gears with small module (e.g. instrument gears). High precision is required.

Heavy-duty hob: For machining gears with large modulus or gears made of hard materials.

Application of Carbide Hob

Automotive industry: manufacturing of transmission gears, differential gears and other key components.

Aerospace: High precision machining of turbine gears and transmission gears.

Energy industry: processing wind power generation gear box, mining machinery gears and other large modulus gears.

Precision machinery: for clocks and watches, instruments and other small modulus gear processing.

Advantages of carbide hobs

High efficiency: suitable for high-speed cutting, significantly reducing processing time.

High precision: ensure tooth shape and surface quality, meet strict tolerance requirements.

Long life: excellent wear resistance, service life is much higher than high-speed steel hob.

Wide adaptability: capable of processing gears made of various materials, such as tempered steel, carburized steel and cast iron.

Precautions for the use of carbide hobs

Optimization of cutting parameters: Carbide hob is suitable for high-speed cutting, but it is necessary to reasonably select the cutting speed and feed to avoid tool overload or chipping.

Cooling and lubrication: using appropriate coolant can reduce cutting heat and prolong tool life.

Avoid strong impact: Cemented carbide material is brittle, so the tool should be avoided from impact or vibration during machining.

Regular inspection and maintenance: monitor the wear condition of the tool and repair or replace it in time to ensure the machining quality.

Precise installation: the installation of the hob needs to ensure concentricity to avoid machining errors caused by eccentricity.

Hunan Jetvision Industrial Co.Ltd is one of the leading Tungsten carbide manufacturers and suppliers with over 20years experience of tungsten carbide products production and technology, It's a professional supplier which provide kinds of tungsten carbide products, such as tungsten carbide cutter blade, carbide ball, carbide ball mill tank, carbide grinding ball jar, cemented carbide rod blank, cemented carbide wire drawing dies, tungsten carbide seal rings, tungsten carbide plate, tungsten carbide bushing, carbide tube, tungsten carbide button, carbide mining inserts, carbide blade, tungsten carbide strip, carbide dies, carbide brazed tips, tungsten carbide no standard products, carbide studs, tungsten carbide customized components which are widely used in machinery, mining, construction, oil and drill, industrial engineering etc.

Keyword: cemented carbide hob supplier, carbide hob manufacturer, carbide hob price, carbide hob supplier, tungsten carbide hob in stock, buy tungsten carbide hob Tungsten carbide cutting tools manufacturer, solid carbide hob price list, hard metal hob supplier, wholesales carbide hob

Prev:Types and Applications of Milling Cutter

Next:Broken Carbide Milling Cutter Edge Wear Reasons and Solutions