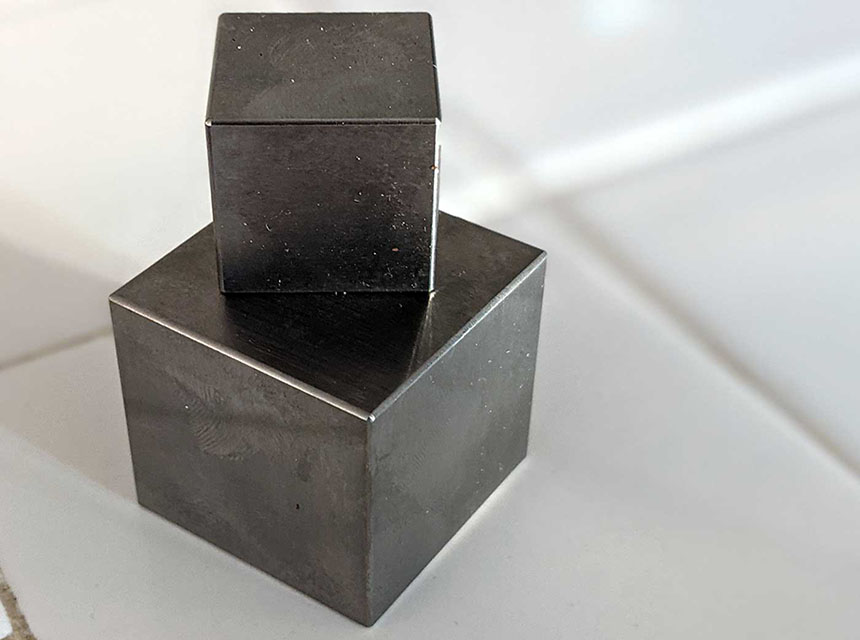

Tungsten Carbide Cube

Cemented Carbide Cube Manufacturer

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan, China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Cutting tools, Wear parts, Mining and drilling, Engineering....

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

Cemented carbide cube, also called tungsten carbide cube or TC cube, is a material made of a combination of tungsten carbide and metallic cobalt by powder metallurgy processes.

Tungsten cylinder block heavy metal cubes

Description of polished surface high strength tungsten cube

Tungsten block cube is a kind of W-based matrix with the W content of 85-99%,Nickel, Titanium also implied.With regular shape, such as square, rectangle and other regular shape. It's have excellent electric and thermal characters with high density, which is much higher than Nickel, Titanium and lead. Tungsten alloy also have good mechanical strength and small coefficient of expansion and large elastic modulus,excellent corrosion resistance and machinability.

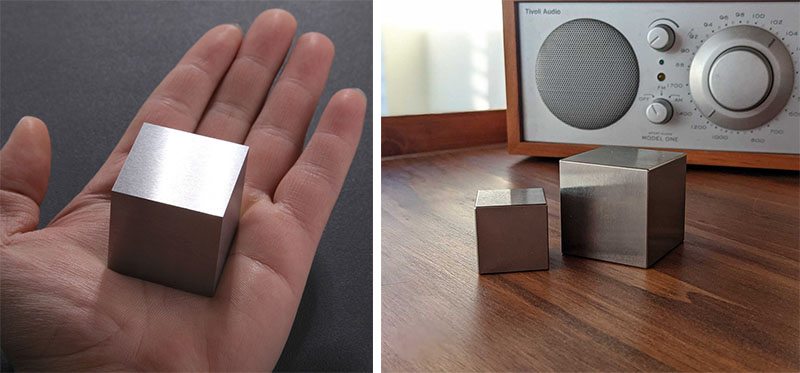

Tungsten Carbide Cube Size

There is no single standard size for a cemented carbide cube, as the specific dimensions will depend on the intended application and manufacturing process. However, some common sizes for cemented carbide cubes used in industrial and scientific settings include:

- 10mm x 10mm x 10mm (0.4 inches x 0.4 inches x 0.4 inches)

- 12mm x 12mm x 12mm (0.5 inches x 0.5 inches x 0.5 inches)

- 15mm x 15mm x 15mm (0.6 inches x 0.6 inches x 0.6 inches)

- 20mm x 20mm x 20mm (0.8 inches x 0.8 inches x 0.8 inches)

Other sizes may be available depending on the drawing or customer’s requirements.

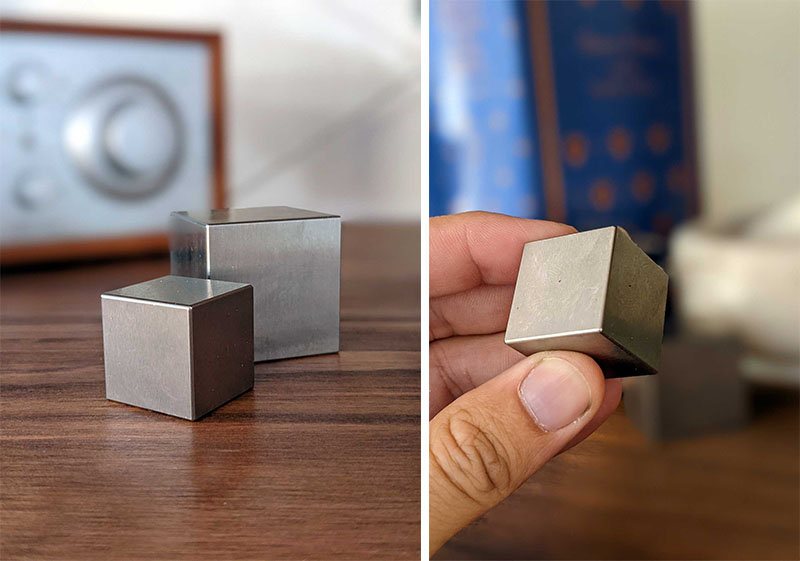

Advantage of tungsten cube and cylinder for counterweight:

1. Good mechanical strength

2. Low thermal expansion

3. Good corrosion resistance

4. High radiation absorption (superior to lead)

5. Simplified life cycle

6. High density, high strength,high impact resistance and crack resistance, etc.

Application

1) Cutting tools: Carbide cubes are used to make cutting tools like drill bits, saw blades, and milling cutters. They can cut through tough materials like metal and concrete with ease.

2) Wear parts: Carbide cubes are used for wear parts like valve seats, piston rings, and bushings. These parts are designed to be durable and long-lasting, even under extreme conditions.

3) Mining and drilling: Carbide cubes are used in mining and drilling applications because of their hardness and durability. They are used for drill bits, mining tools, and roadheader picks.

4) Engineering and manufacturing: Carbide cubes are used in many engineering and manufacturing applications, including tooling, dies, and molds. They are also used in aerospace and automotive industries for parts that need to withstand high temperatures and pressures.

5) Jewelry: Carbide cubes are used to make jewelry because of their hardness and scratch resistance. They are often used for wedding bands and other types of rings.

Keyword:

Tungsten carbide cube

Tungsten carbide Centimetre Scale Cube

Tungsten Carbide Calibration Cube

Pure Tungsten Carbide Cube

Polished carbide cube