Tungsten Carbide Wire Stripping Machine Blade

Tungsten Carbide Wire Stripping Machine Blade

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

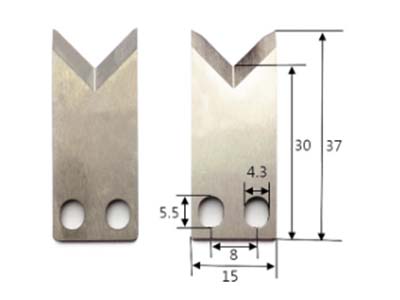

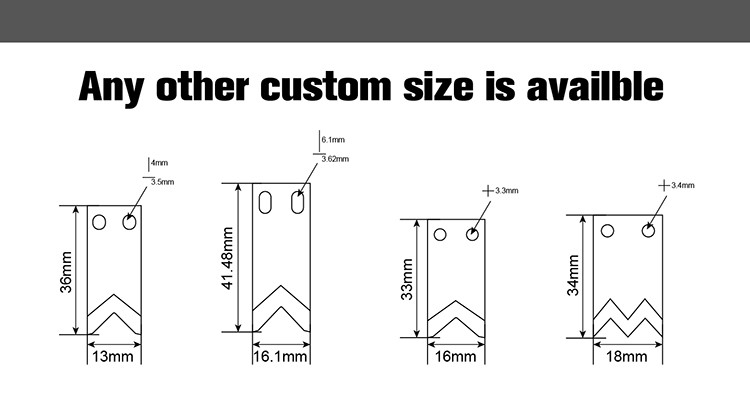

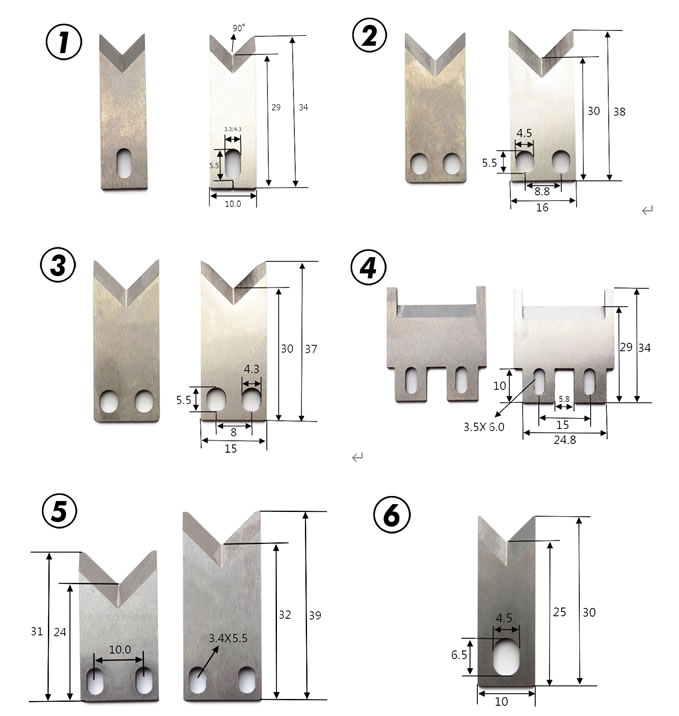

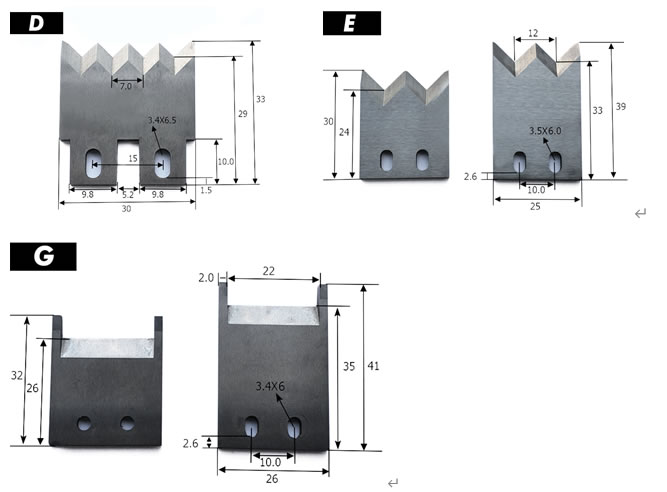

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Wire processing,electrical cable cutting and stripping

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

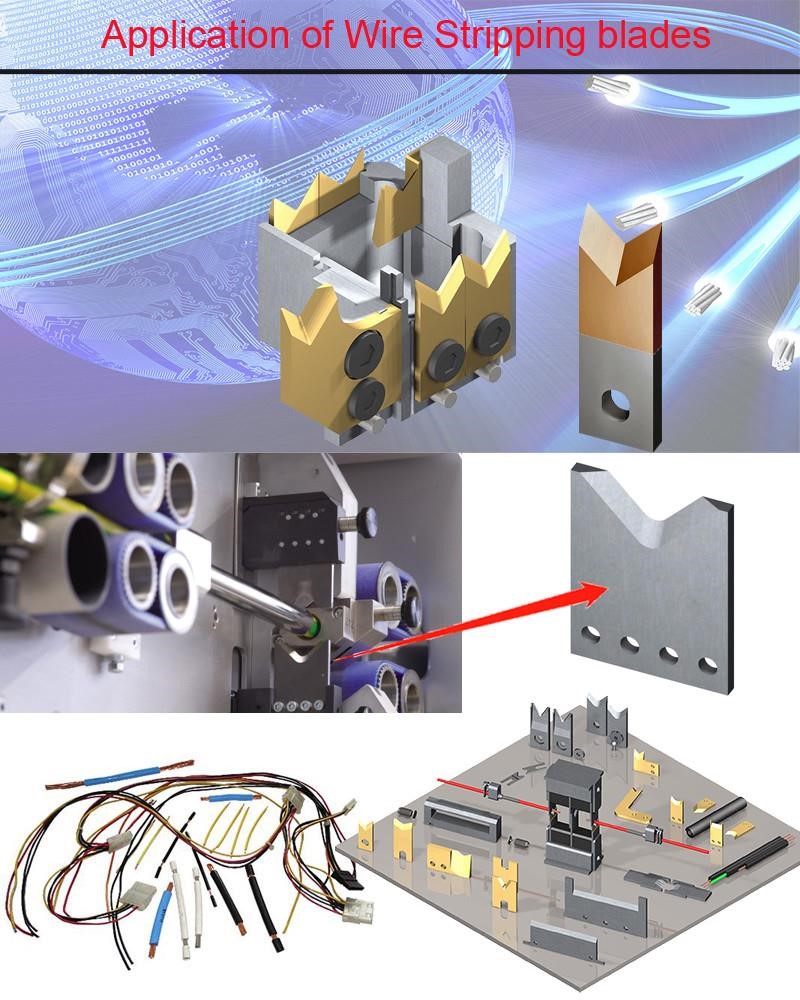

Product description

Due to the processing of wire is very high hardness and wire stripping machine is working extremely fast.Wire stripping blade need to be fully high hardness and wonderful wear resistance.Generally, wire stripping blade is made by tungsten carbide or HSS material .But tungsten carbide is the suggested material for better performance.because It is high hardness,good wear resistance ,strength and toughness,favourable heat resistance,corrosion resistance etc excellent properties.Tungsten carbide wire stripping blade is keep stable cutting performance even if working condition is under 500 or 1000℃. As a result ,tungsten Carbide wire stripping blade is highly recommended to be your first choice. Also, we can provide customized services, just give us your Technical drawings or samples.

TYPE | Cable Stripping Machine Blade |

Material | Tungsten Carbide |

Hardness | HRC40-90 |

Precision | ±0.02 mm |

Sharpness | 18N-30N |

Edge trimming | NC grinding |

Coating | Customized(TiN TiC,TiCN TiAN CrN..etc) |

Application | Wire processing,electrical cable cutting and stripping |

Other Tungsten carbide Wire Stripping Machine Blade you might like :

Application: Electronic wire processing industry, machinery and terminals Industry

Wire stripping blade can strip various types of wire materials: copper core wire, aluminum core wire, computer core, isolation wire, telephone wire, PVC plastic wire, silica gel braided wire, electronic wire, high-temperature wire, cable, short thin wire, large square wire, flat wire, sheath wire and coaxial line. The stripping process can be divided into wire cutting, single end peeling, double end peeling, single end pressing and double end pressing.

Lead time:

We will provide the price and delivery time when we quote. Generally, it will take 3-10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Packing details:

Customized own-brand packaging is highly recommended.