Carbide Circular Blade for Tobacco

Tungsten Carbide Tobacco Round blade

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

- Size:

- 40*8*0.35 or Customized, OEM Accepted,Customer Request

- Usage:

- For cigarette making industry, for cutting tobacco, paper cutting, film, foam, rubber,foil, graphite

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

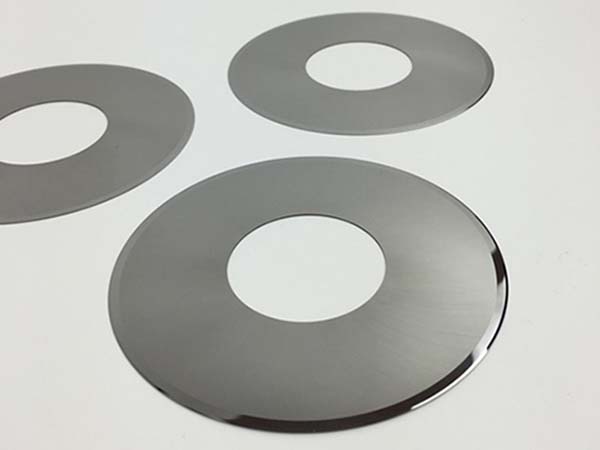

High Hardness TC material Slitting Circular Blades Cutter Cutting Circular Knife Blade for Tobacco Circular Blade, OEM ODM Circular Carbide Blade For Cigar Making Knife Tobacco Cigarette Cutting Core, Top Quality and Low Factory Price Carbide Round Circular Blade for Tobacco Supplier

Tungsten Carbide Tobacco Round blade is a blade specially designed for cigarette production.

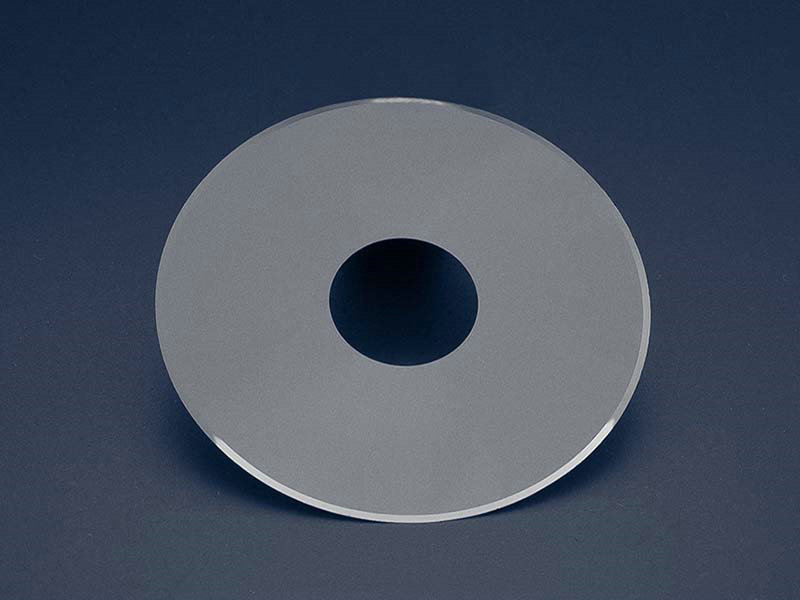

They are made of durable sub-micron tungsten carbide grade. Precisely ground with sharp cutting edges, polished on both sides, to achieve good finished of cut, and longer life time, to keep production running smoothly and efficiently. Recommend material grade like YG8/K30, YG10/K35. We produce high quality tungsten carbide Tobacco and Cigarette slitting blades and knives for tobacco and cigarette industry.

Material: K8 Tungsten Carbide Tobacco Round blade; K30 Tungsten carbide circular slitting knives for cigarette filter cutting.

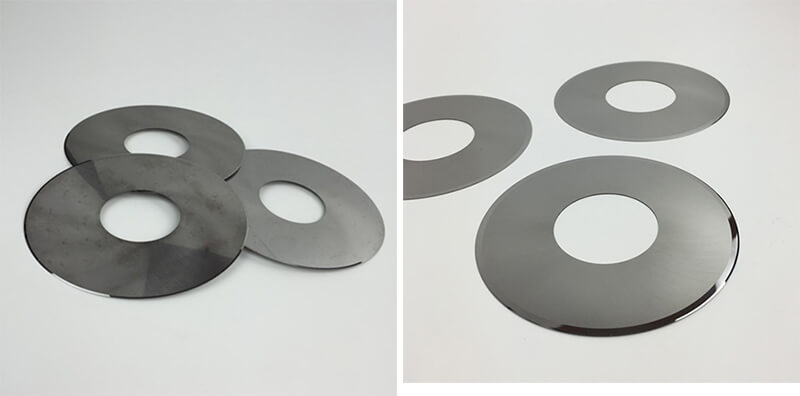

Normal Size:

Item | Dimensions(mm) |

1 | 40*8*0.35 |

2 | 60*19*0.27 |

3 | 61*19.05*0.63 |

4 | 63*19.05*0.254 |

5 | 63*19.05*0.3 |

6 | 63*15*0.3 |

7 | 63*19*0.35 |

8 | 75*10.05*0.6 |

9 | 85*16*0.25 |

10 | 85*16*0.35 |

11 | 89*15*0.38 |

14 | 100*15*0.35/0.2/0.3 |

15 | 100*16*0.2/0.3 |

17 | 100*45*0.2 |

18 | 110*22*0.5 |

19 | 140*46*0.5 |

We can produce on the standard sizes, and also various customized sizes. | |

Advantage:

1. Good quality, long service life, high cost performance.

2. Good cutting effect, no burr cutting surface, no processing traces.

3. High precision and excellent abrasion resistance.

4. Reliable performance (less machine downtime)

Application:

For cigarette making industry, for cutting tobacco, paper cutting, film, foam, rubber,foil, graphite and so on.

Processing

Production process of carbide round blade blank material

Select tungsten carbide powder + cobalt powder according to applicable requirements

Mix thoroughly

Crushing

Drying

Sieve and add molding agent

Re-drying

Sieved to make the mixture

Granulating and pressing the mixture

Forming

Low pressure sintering

Sintered blank

Inspection

Blank dimensional accuracy inspection.

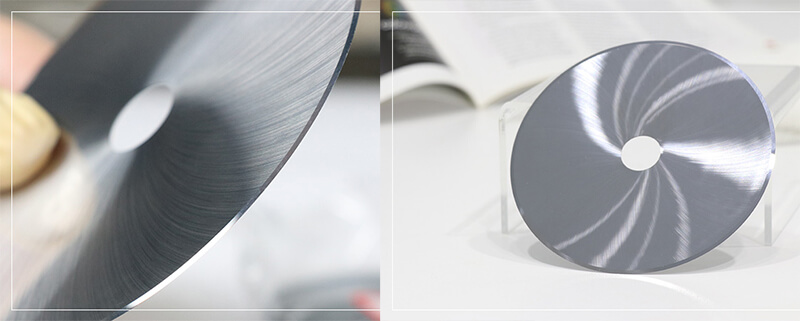

Cemented Carbide Circular Blade Finishing and Forming Process

Finishing grinding of blade surface

Finishing grinding of inner circle and positioning groove

Grind the outer circle of the blade and rough cutting edge

Fine cutting edge

Appearance and dimensional accuracy inspection

Machine Test

Marking

100% microscope inspection of the cutting edge

Qualified product packaging

Packing

Finished product-Manual testing-Machine testing-Cleaning-Packing-In carton/as request.

KeyWords:

Tungsten carbide circular slitting knives for cigarette filter cutting

Tungsten Carbide circular blade for tobacco

Tungsten Carbide Round blade

Tungsten Carbide Tobacco Round blade

Tungsten Carbide circular blade

Tungsten Carbide round knife blades for tobacco/dried fruit cutting industrial machines

Tungsten Carbide round circular blade for tobacco/Cigarette

Tungsten Carbide Circular Blade Knife For Tobacco Cigarette Filter Slitting Cutting Machine