Cemented carbide seal ring

Cemented carbide seal ring

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- oil refineries, petrochemical plants, fertilizer plants and pharmaceutical, pharmaceutical

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

Cemented carbide seal ring is a powder metallurgy seal ring made of carbide (WC, TiC) micron-level powder of high hardness refractory metals as the main component, with cobalt (Co) or nickel (Ni), molybdenum (Mo) as the binder, pressed into a ring shape and sintered in a vacuum furnace or hydrogen reduction furnace.

The cemented carbide seal ring has a matrix consisting of two parts: one part is the hardened phase; the other part is the bonded metal.

According to the customer's different use environment to produce the corresponding grade of carbide seal ring, specifications are also available in a variety of diameters, with the seal ring series of glossy surface, abrasive surface, concave surface, convex surface grinding equipment and capabilities to provide customers with better service.

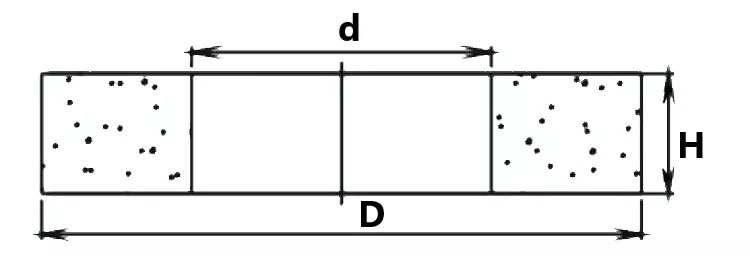

D(mm) | d(mm) | H(mm) |

10~500 | 2~400 | 1.5~300 |

Tungsten Carbide seal ring technical requirements

l Carbide grades for carbide rings and their physical, mechanical properties and gold content in accordance with the provisions of the relevant standards.

l The edge of the blank, the depth of the corner is not greater than 0.33mm.

l The surface of the blank shall not have defects such as skin, blistering, delamination, cracks, porosity, over-burning, under-burning, etc.

l The structure of the blank section should be uniform, no black heart, bubbles, delamination, cracks, severe carburization, decarburization, pressure difference and other defects.

Material Grade:

K10 Carbide seal ring; K20 carbide Mechanical seal ring; K30 Silicon Carbide Seal Ring; K40 Tungsten Carbide Seal Rings.

Chinese Grade | Equal to ISO Category Number | Chemical Composition | Physical Mechanical Properties | |||

WC | Co | Density | Bend Strength | Hardness | ||

% | % | G/Cm3 | N/mm2 | HRA | ||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 |

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 |

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 |

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 |

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 |

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 |

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 |

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 |

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥85.5 |

YG30 | G60 | 70 | 30 | 12.8 | ≥2750 | ≥82 |

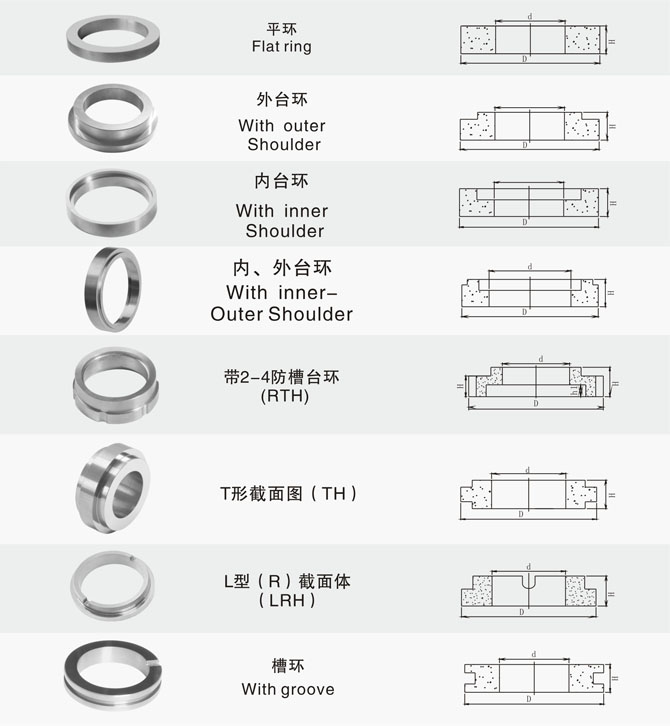

Different types for your choice

Carbide Flat seal ring

Carbide seal ring with groove

Carbide seal ring with outer shoulder

Carbide seal ring with inner shoulder

Application:

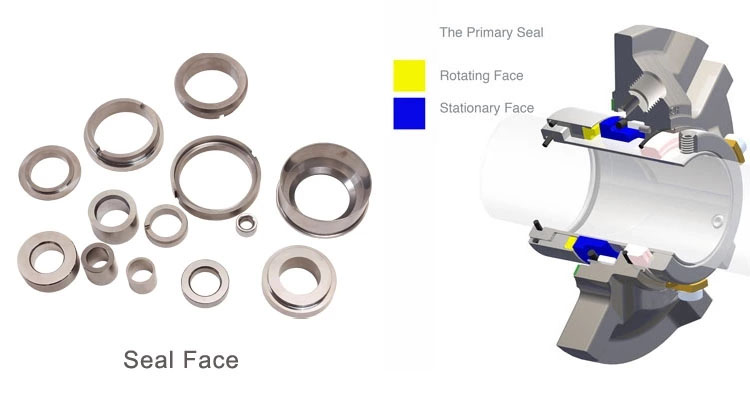

Cemented carbide seal ring has the characteristics of high wear resistance, high corrosion resistance and good compression performance, used as mechanical seals, such as compressors and mixing equipment, in oil refineries, petrochemical plants, fertilizer plants and pharmaceutical, pharmaceutical and other industries in large quantities.

Carbide seal ring

high precision Carbide seal ring

Cemented carbide seal ring

Tungsten carbide seal ring

PM Tungsten Carbide Seal Ring

Tungsten carbide Mechanical Seals

TUNGSTEN CARBIDE SEAL RING FOR GOULDS PUMPS

Tungsten Carbide Flat Seal Ring for Mechanical seal ring