Tungsten Carbide Bushing&Sleeve

Tungsten Carbide Bushing&Sleeve

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

- Size:

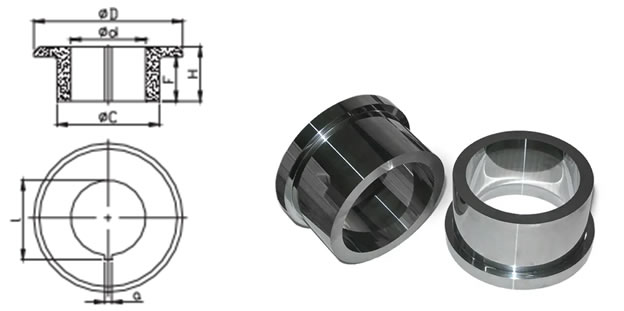

- T model Sleeves, Straight Sleeves or shaped.

- Usage:

- Petrochemical industry

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

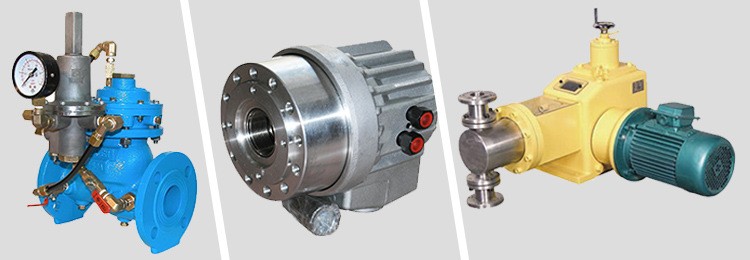

Tungsten carbide bushing production and processing of high-strength, can withstand prolonged load, with high chemical stability,alkali, alcohol, ether, hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics, tungsten carbide sleeve widely used in petrochemical industry for Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

Dimensions:

D(mm) | d(mm) | H(mm) |

10~450 | 3~360 | 8~260 |

Multiple product specifications and models, can be supplied according to customer requirements.

Advantages:

l Advanced process design

l Specialized in production

l Unique material properties

l Personalized customization

l Whole process quality control system

l Strong supply ability guaranteed

Material Grade

Excellent material-K10 carbide K20 carbide K30 Carbide bushing:

Chinese Grade | Equal to ISO Category Number | Chemical Composition | Physical Mechanical Properties | |||

WC | Co | Density | Bend Strength | Hardness | ||

% | % | G/Cm3 | N/mm2 | HRA | ||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 |

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 |

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 |

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 |

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 |

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 |

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 |

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 |

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥85.5 |

YG30 | G60 | 70 | 30 | 12.8 | ≥2750 | ≥82 |

Various types or customized parts for your option:

Tungsten Carbide K10/K20/K40/G60 T model Sleeves

Tungsten Carbide K10/K20/K40/G60 Straight Sleeves

Tungsten Carbide K10/K20/K40/G60 Special/shaped Sleeves:

Applications:

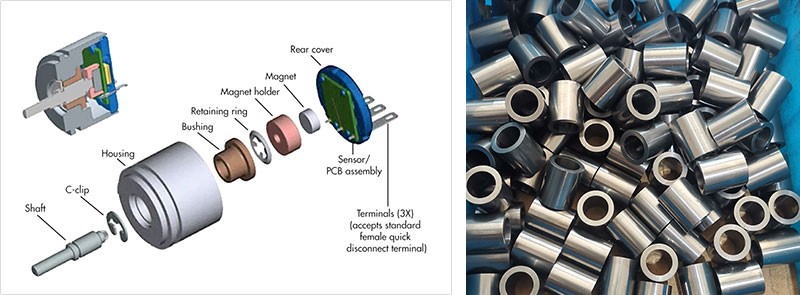

Tungsten carbide bushing applications is widely, which is a device to protect a class of components. It is in the actual work and the role and purpose of its application environment have a great relationship. Valve applications, bushings be installed in the valve stem cap trap, in order to reduce the valve leakage, to seal; bearing applications, the use of bush to reduce wear between the bearing and the shaft seat, avoid the gap between the shaft and the hole increases and so on.

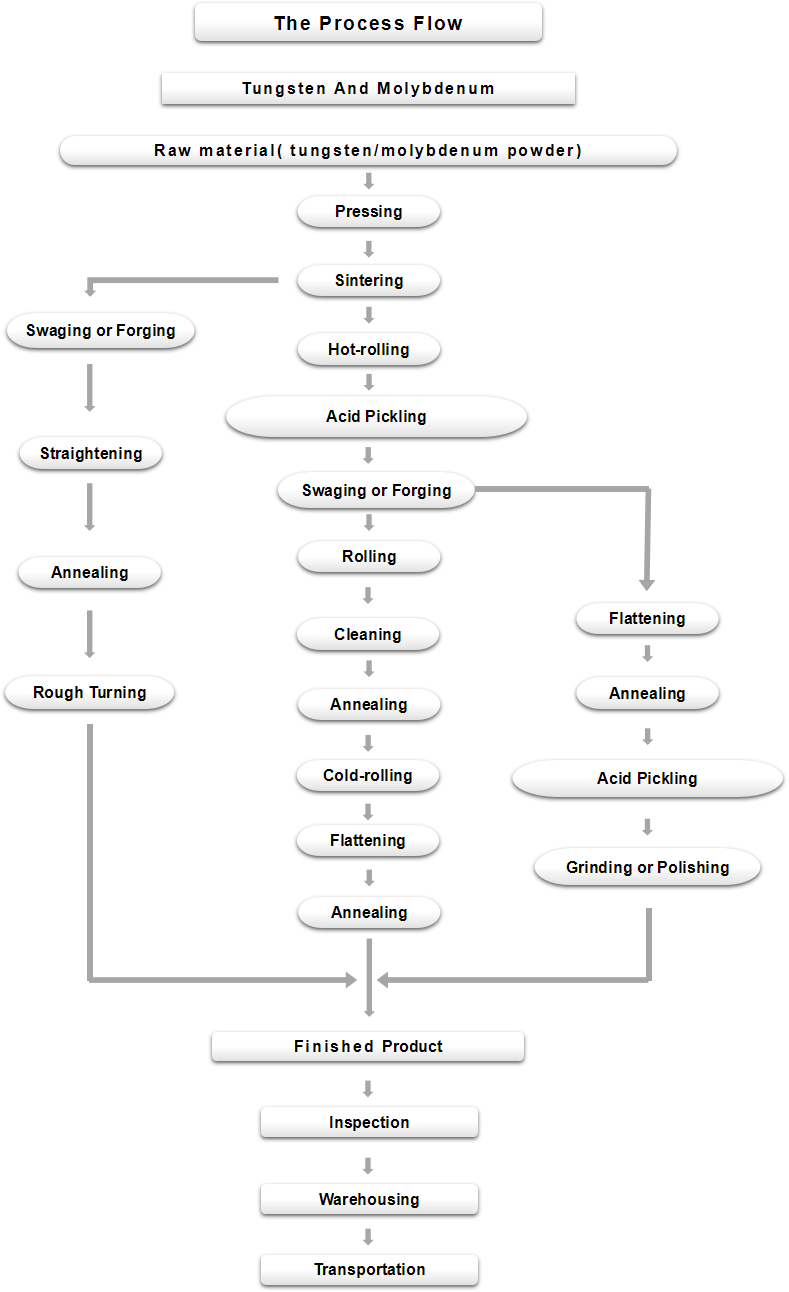

How to produce carbide products

Tungsten Carbide Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering →blanks→Flaw inspection→Packing→Warehousing

Solid Tungsten Carbide Bushing

Cemented Bearing Bushing

K20 Cemented bushing

tungsten carbide bushing

K10 K20 Tungsten carbide shaft wear sleeve

Tungsten Carbide Sleeve Mechanical Seal Bushing

Hydraulic Parting Oil Seal Bushing Tungsten Carbide Bushing Seal Sleeve

Solid Tungsten Carbide Velocity Control Trim of Axial Choke Valve Carbide Bushing

Tungsten Carbide Bushing with mirror polishing

Shaft Bearings - Carbide Bushings and Sleeves

Tungsten carbide bushing and sleeves

Tungsten carbide guide bushing

Tungsten carbide Pump Bush

Tungsten carbide sleeve drill bush bearings shaft sleeves

Tungsten carbide flanged bearing bush