Tungsten Carbide Pin Punch

Tungsten Carbide Pin Punch

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

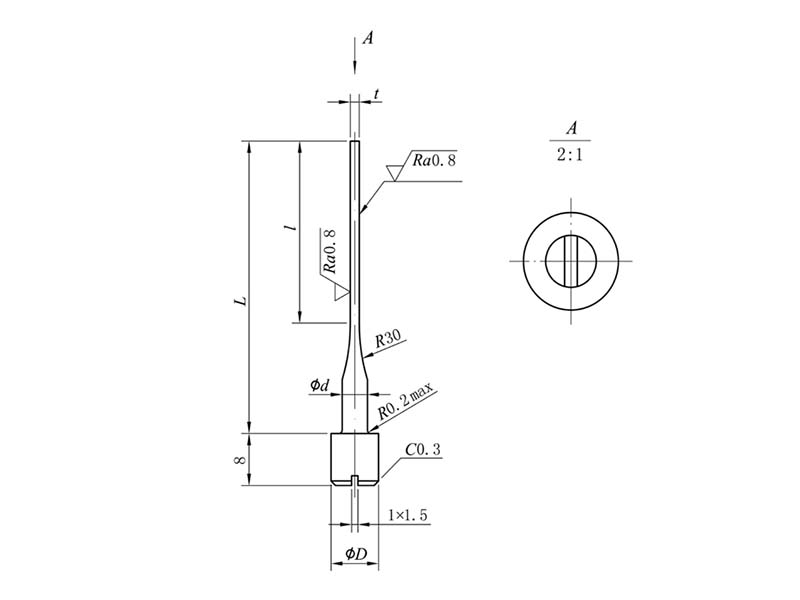

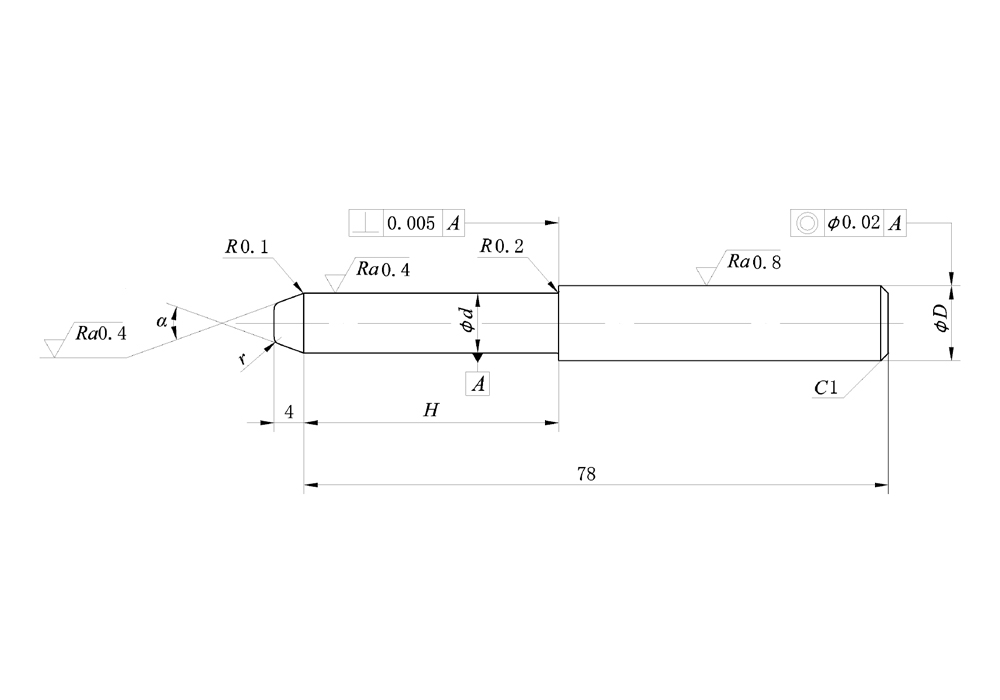

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Punching purposes in pylon factories

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

Carbide punches are also called carbide convex dies, carbide upper dies, carbide male dies, etc. Punch pins can be divided into SKD punch pins, SKH punch pins, and ASP punch pins according to the selection of materials. Also punch pins can be divided into guide punches, child punches hexagonal punches, oval punches, forming punches, fan punches, shaped punches, etc. according to the shape and usage.

Punching needles are metal parts mounted on stamping dies and applied in direct contact with the material to deform it and cut it. Carbide punch pins are an essential accessory when working with stamping dies and are replaceable die consumables. Tungsten carbide punch according to the different materials and thickness of the stamping, to choose a different carbide, in general, the thicker the product being stamped, the lower the hardness of the carbide the better the toughness of the model, the harder the material, choose a slightly lower hardness of the model, so that you can effectively avoid punching the needle is missing. The thinner the plate, or the hardness is not high, this kind of product hole processing, tungsten steel punching needle can be used with higher hardness, so as to improve the service life of the punching needle. Tungsten steel punched needles can be made in different shapes according to the different needs of the product, for example, the computer case, there are a lot of heat dissipation holes, and cell phones, many electrical appliances, mechanical hole processing.

The role played by tungsten carbide punching needles in stamping dies.

l As a key component of the stamping die, the punch pin is mainly used for continuous blanking stamping processing punching off operation on the stamping die, so that the material to be stamped and processed is separated or plastic deformed, and then the required finished or semi-finished product is obtained. This is the stamping die in the stamping process, the material stamping processing into the required parts. It is more common in the production of hardware parts and metal panel punching for cell phones.

l Punching needle made of tungsten steel is an indispensable accessory when stamping dies are working, and it belongs to the replaceable die consumables.

Machining and manufacturing process of carbide punches

l Drawing and cutting.

l Heat treatment. Flattening - fine quenching heat treatment - warm tempering treatment.

l Grinding processing. According to the requirements of the various pointed base angle of the punch, respectively grinding molding processing.

l Polishing (oil and rust removal).

l Activation treatment.

l Surface cleaning.

l Inspection and storage.

Applications

Carbide punch is used together with punch bar, punch nut and punch master. It is generally used for punching purposes in pylon factories. When punching, it takes less than a second for a large punching machine to process hundreds of holes at the same time, which dramatically increases production efficiency. Therefore, carbide punches are widely used in machinery manufacturing, automobile manufacturing, aviation manufacturing and other fields.

Material Grade: K10 Tungsten carbide punches for nail making

Chinese Grade | Equal to ISO Category Number | Chemical Composition | Physical Mechanical Properties | |||

WC | Co | Density | Bend Strength | Hardness | ||

% | % | G/Cm3 | N/mm2 | HRA | ||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 |

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 |

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 |

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 |

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 |

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 |

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 |

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 |

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥85.5 |

YG30 | G60 | 70 | 30 | 12.8 | ≥2750 | ≥82 |

NOTE: Available in Standard and Non- Standard sizes as required by Customers.