Tungsten Carbide Screw Dies&Nut die

Tungsten Carbide Screw Dies&Nut die

- Material:

- 100% Virgin Tungsten Carbide or carbide to steel assemblies

- Place of Origin:

- Hunan China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Fastener manufacturer industry

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

The durability of tungsten carbide cold heading die is more than ten times or even dozens of times that of steel die. Carbide cold heading die has the characteristics of high hardness, high strength, corrosion resistance, high temperature resistance and small expansion coefficient.

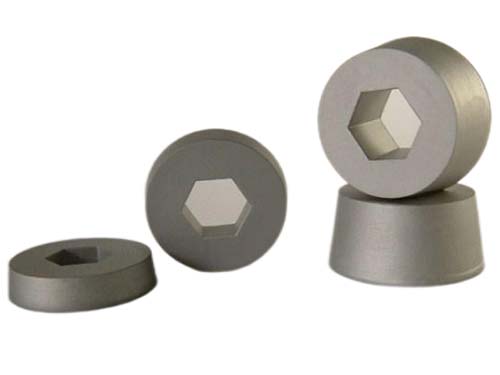

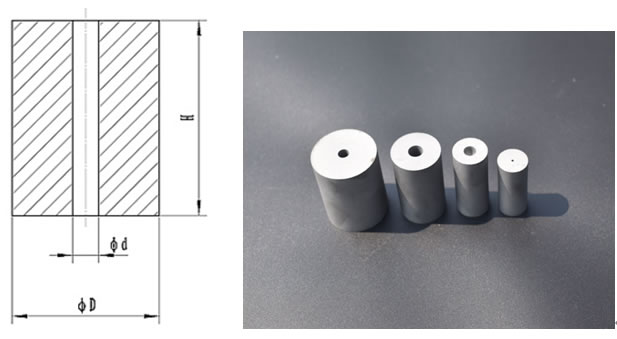

The carbide screw dies mainly include main die, pre-punching die, cemented head punching die, solid carbide forming die, tungsten carbide cutting die, cutter, carbide to steel assemblies nut die, carbide six-flap combination die, cemented multi-station die, carbide hexagonal punching light die, hexagonal cutting edge die, die shell, thimble, etc..

K40 Carbide Screw Dies:

Carbide Nut Dies/ carbide to steel assemblies nut dies are exclusively used in fasteners industry to make fasteners of high strength and high specification required for specific purposes by the various industries. Hexagonal, Square & Round are the most common shapes of nuts are designed from these Dies of high strength that can bear large impact of pressure and stress. Both standard and non standard nuts are manufactured by using these high quality Dies. Material used in making these Dies is very much specific having unique composition to provide certain essential characteristics of strength, perfection, anticorrosion property with super fine and smooth finish of international standards.

Various Grades for Options:

Tungsten Carbide Cold Forging/heading Dies | ||||

Grades | Density | T.R.S | Hardness | Performance & application recommended |

g/cm³ | MPa | HRA | ||

YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

YG15/K30 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. |

YG20/K30 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. |

YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. |

YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. |

YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

YG20C/K40 | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. |

YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. |

YG25C | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. |

Application:

Tungsten carbide nut forming dies are efficiently used in metal industry (fastener manufacturer industry) for the production of high quality nuts.