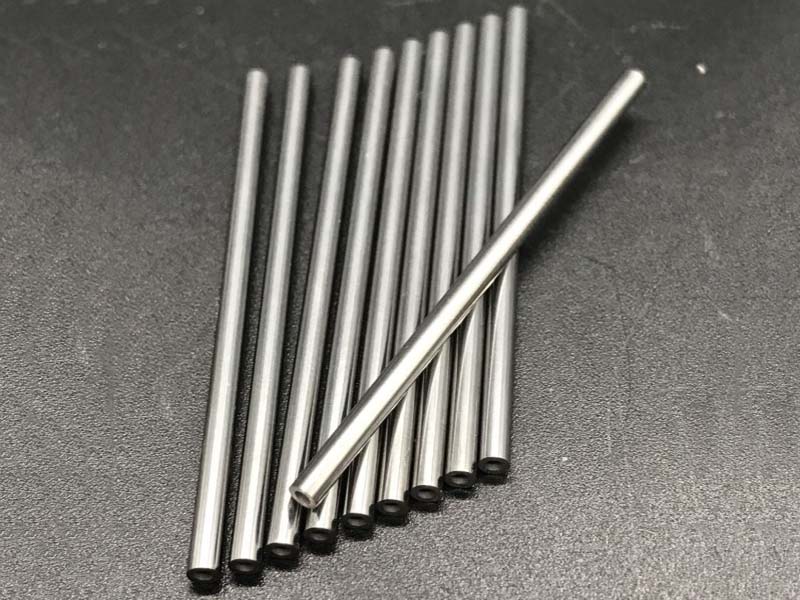

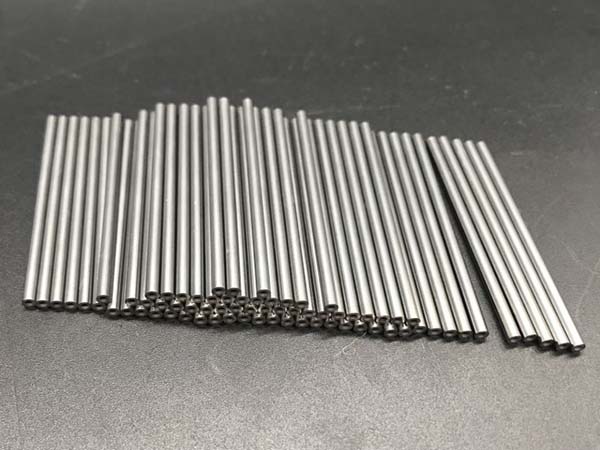

Tungsten Carbide Tube/Pipe

Tungsten Carbide Tube

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- body components, oil pump seals, thermocouple protection tube, sapphire crystal furnace and high temperature furnace.

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

Tungsten Carbide tube is mainly made of WC and Co by powder metallurgic method processing. We mainly provide the tungsten carbide tube, which production under CIP production with good density and higher bending strength.

Features of Tungsten carbide Pipe:

l The surface of tungsten carbide tube is silver gray metallic luster;

l The purity is no less than 99.95%;

l Its density is more than or equals to 18.8g/cm3;

l The production processes of tungsten tube include isostatic pressing, IF induction sintering, CNC vertical turning, CNC milling, coreless grinder and wire cutting;

l The tungsten carbide tubes we produced are with high-precision, finish surface, straight size, and high temperature deformation.

l There are two kinds of tungsten tubes: one is with diameter 8--70 mm, wall thickness more than 3mm, maximum length 300mm and density no less than 18.8g/cm3. Another one is with diameter 70—500mm, wall thickness more than 8mm, maximum length 700mm and density no less than 18.3g/cm3.

Application:

Tungsten Carbide tubes mainly used for body components, oil pump seals, thermocouple protection tube, sapphire crystal furnace and high temperature furnace. We Can be customized as per customers requirements and welcomed the drawing.

Common grades: K10 Non-standard Size Customized Tungsten Cemented Carbide Pipes, K20 carbide square bars, K30 carbide tubes.

Chinese Grade | Equal to ISO Category Number | Chemical Composition | Physical Mechanical Properties | |||

WC | Co | Density | Bend Strength | Hardness | ||

% | % | G/Cm3 | N/mm2 | HRA | ||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 |

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 |

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 |

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 |

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 |

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 |

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 |

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 |

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥85.5 |

YG30 | G60 | 70 | 30 | 12.8 | ≥2750 | ≥82 |

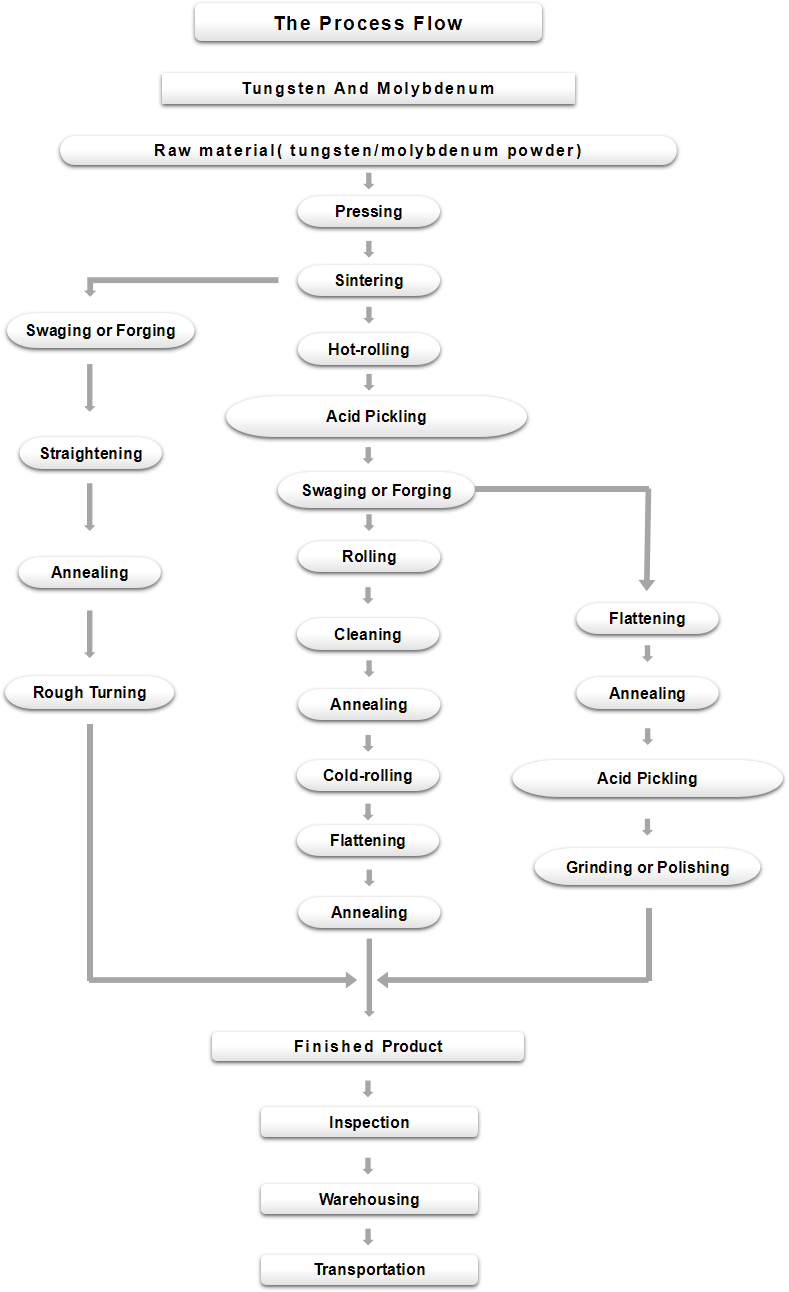

Main Process flow:

Tungsten Carbide Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering →blanks→Flaw inspection→Packing→Warehousing