Tungsten Carbide strip

Tungsten Carbide Strip Supplier and Manufacturer

- Material:

- 100% Virgin Tungsten Carbide

- Place of Origin:

- Hunan China

- Size:

- Customized, OEM Accepted,Customer Request

- Usage:

- Woodworking, metalworking, tooling, petroleum machinery, textile tools and other industries

- Delivery Time:

- in stock or 25-45 days

- Payment Terms:

- T/T, Western Union

Product description

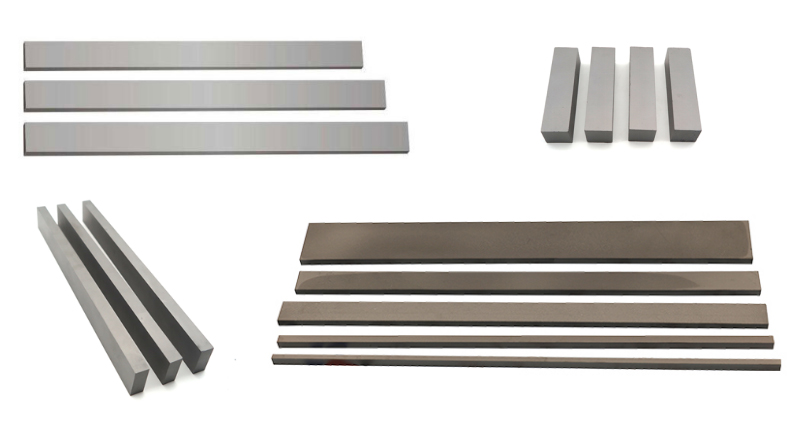

Tungsten Carbide Strip is also known as Rectangular Tungsten Carbide Bar, Tungsten Carbide Flat Bar. Available in various sizes and shapes, with or without edges; with or without magnetic properties. The production process is similar to other tungsten carbide products like carbide rods, carbide plate, and is widely used in many fields. Shaped parts and size can be manufactured according to drawings.

Cemented carbide rectangular bars are mainly made of tungsten carbide and cobalt (nickel) powder through powder metallurgy methods. The main production processes for carbide rectangular bars are powder grinding, ball milling, pressing and sintering. For different applications, the content of WC and Co in carbide rectangular bars is different. We can produce the customized shaped parts according to your drawings.

Common grades: K10 Carbide rods, K20 carbide square bars, K30 carbide strips.

Chinese Grade | Equal to ISO Category Number | Chemical Composition | Physical Mechanical Properties | |||

WC | Co | Density | Bend Strength | Hardness | ||

% | % | G/Cm3 | N/mm2 | HRA | ||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 |

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 |

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 |

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 |

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 |

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 |

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 |

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 |

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥85.5 |

YG30 | G60 | 70 | 30 | 12.8 | ≥2750 | ≥82 |

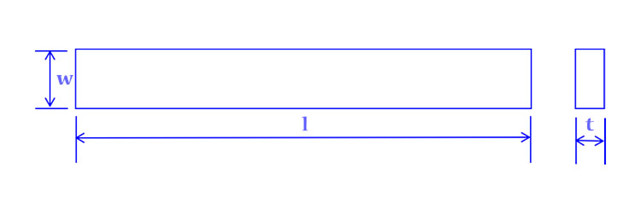

Size: various specifications of the Carbide flat bar sintered in different grades and lengths, on demand:

Grade | SIZE | L | W | T |

K10 K20/K30 YS2T | 100×W×T | 100-0.5 +0.5 | 6-25( -0.3 +0.3) | 1.5-10 (-0.2 +0.2) |

140×W×T | 140-0.5 +0.5 | 6-25 (-0.3 +0.3) | 1.5-10 (-0.2 +0.2) | |

160×W×T | 160-0.5 +0.5 | 6-40( -0.3 +0.3) | 1.5-10 (-0.2 +0.2) | |

230×W×T | 230-0.5 +0.5 | 8-40 (-0.3 +0.3) | 2-10 (-0.2 +0.2) | |

320×W×T | 320-0.5 +0.5 | 8-40 (-0.3 +0.3) | 2-10 (-0.2 +0.2) | |

Note: The sizes not listed in the table can be produced according to customers' requirements. | ||||

Application:

Carbide flat bars are mainly used in woodworking, metalworking, tooling, petroleum machinery, textile tools and other industries. The solid carbide square bar is mainly used for processing solid wood, density board, gray cast iron, non-ferrous metal materials, chilled cast iron, hardened steel, PCB, brake materials, etc. Carbide strips of suitable material should be selected according to the material for specific applications.

Main Process flow:

Tungsten Carbide Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering →blanks→Flaw inspection→Packing→Warehousing

Key Words:

Blank Tungsten Carbide Strips

K10 K20 K30 Tungsten Carbide Bar

Polished Tungsten Carbide Strips

Tungsten Carbide Flat Bar

carbide flat bar cemented carbide plate blanks

Cemented Carbide Rod

tungsten carbide flats

Carbide flat bar sintered in different grades and lengths

Cemented carbide long & thin strips

Carbide Flats for Stone Crusher Machine

Rectangular Tungsten Carbide Bar